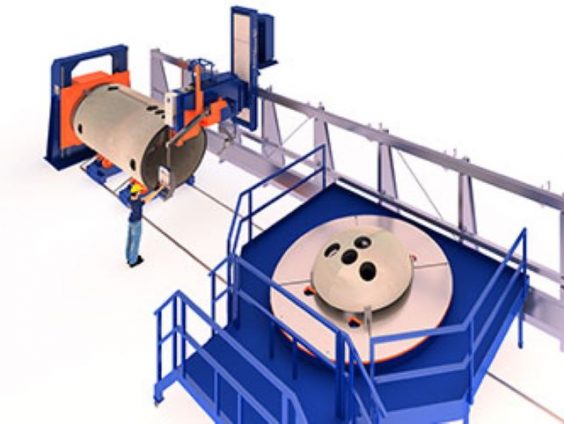

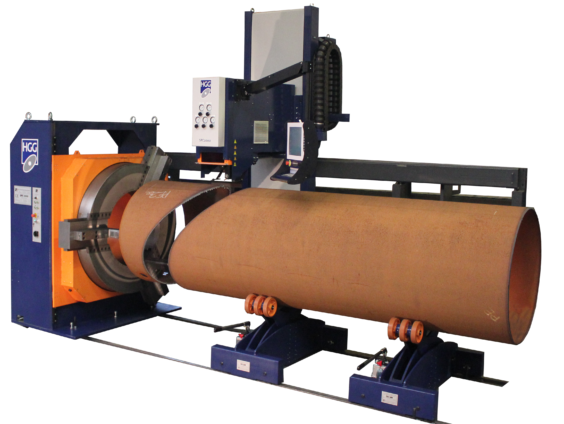

HGG Pipe and Vessel Cutting Machine SPC 1500 – 3000 VHC

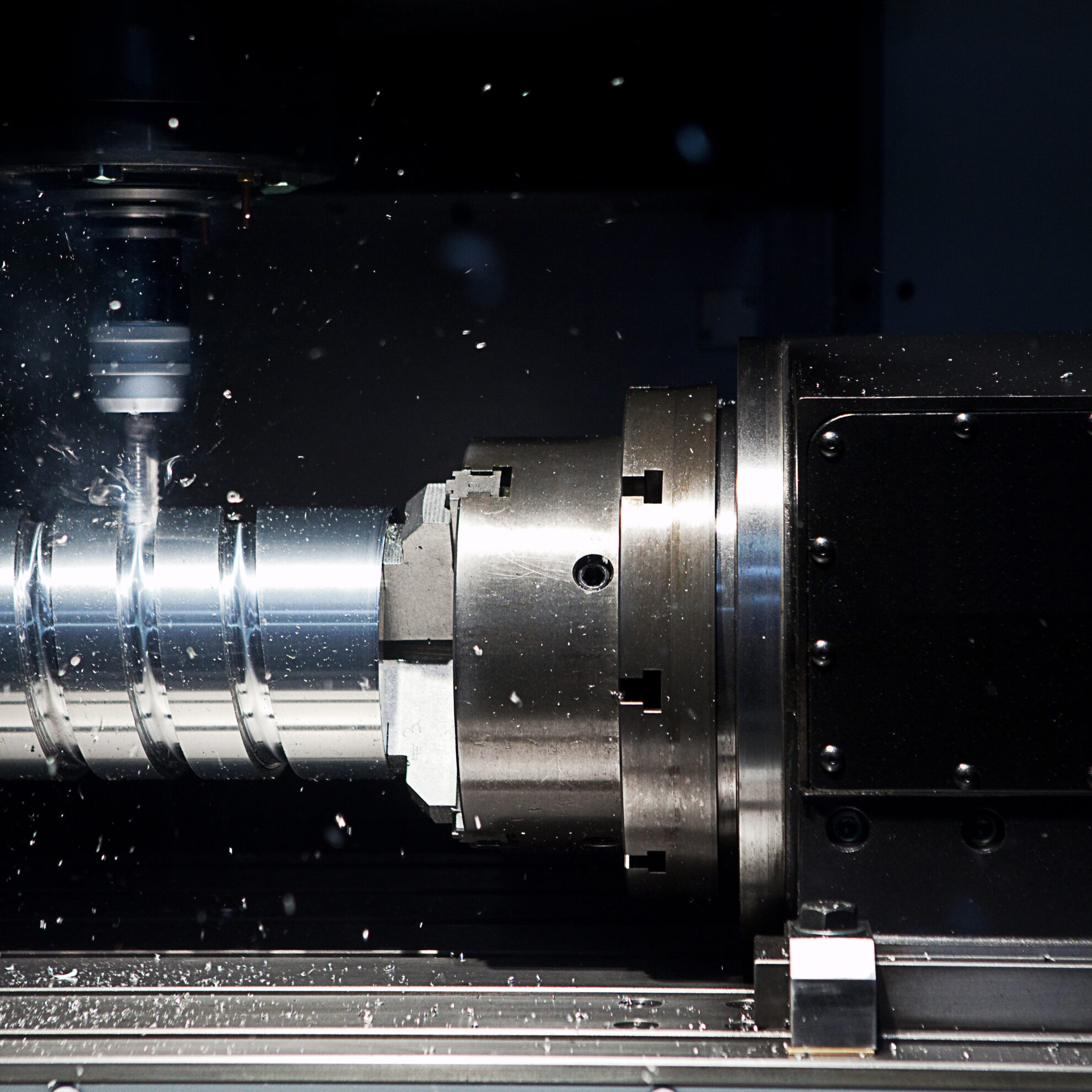

The SPC pipe and vessel head cutting machine is the answer to pressure vessel manufacturers spending too much time on lay-outs. The SPC-VHC saves fabricators time on laying out, cutting, fitting and welding.

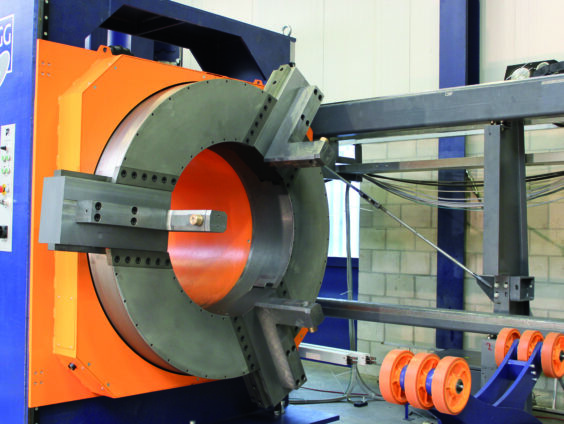

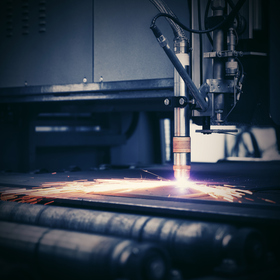

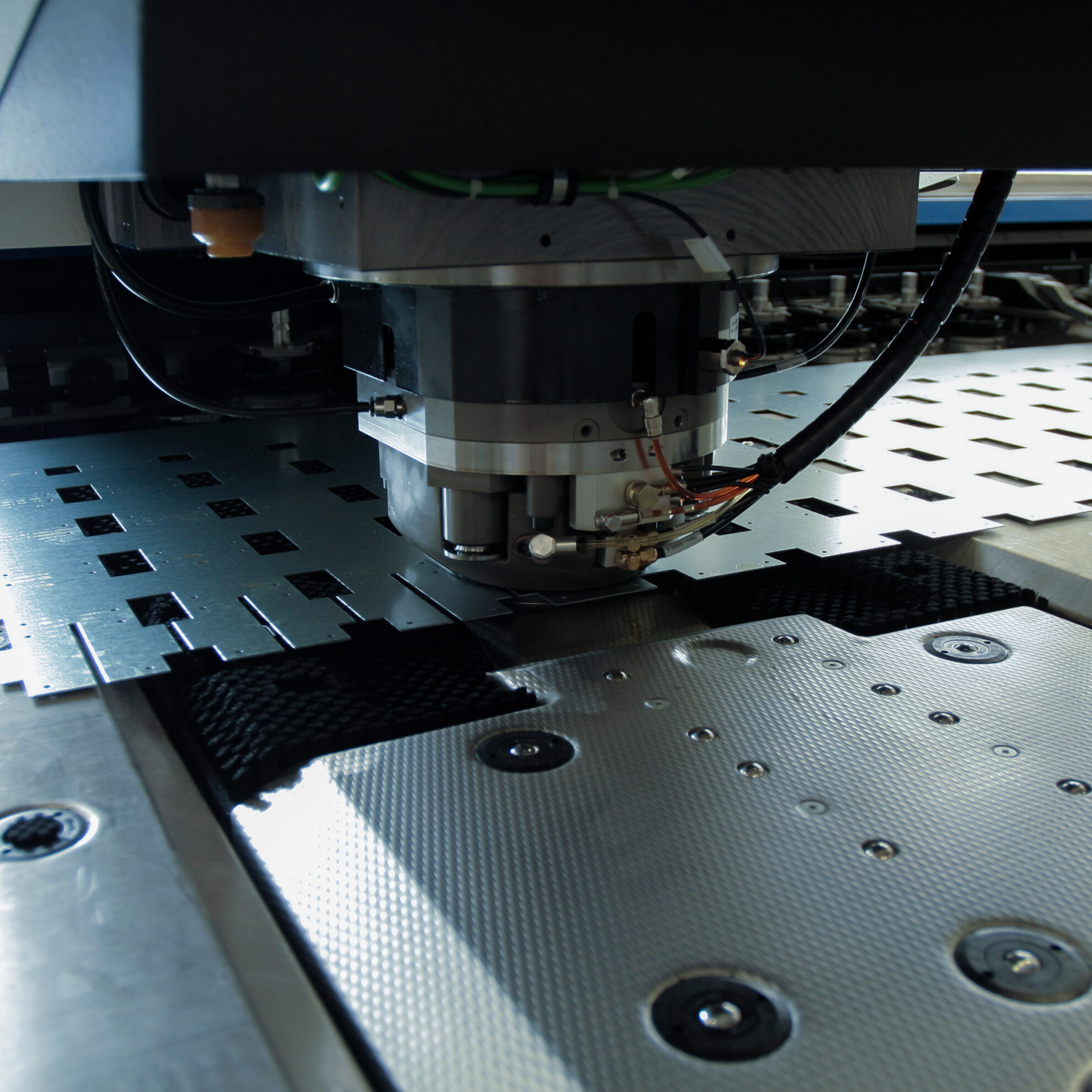

Vessel fabrication is labor intensive and skilled craftsmanship is rare. That is why HGG automates key elements in the process of making vessels by integrating work preparation, laying out, cutting and beveling into one machine – the SPC VHC – a dedicated vessel profiling machine for beveled cutting of both vessel heads and shells. The SPC VHC is the ideal solution for vessel cutting, capable of cutting vessel heads, shells, nozzles, reinforcement pads and hillside holes, all with a bevel to create weld preparation and all on the same machine.

| SPC 1500 VHC | 1525 mm (60”) | 30t | 6–12 m (20’–40’) |

| SPC 2000 VHC | 2035 mm (80”) | ||

| SPC 2500 VHC | 2500 mm (98”) | ||

| SPC 3000 VHC | 3000 mm (118″) | 60t |