Metal stamping

Stamping or pressing is a manufacturing process used to work flat metal sheets into a final shape. In this process, a flat sheet of metal, either in billet or coil form, is placed in a die, where the surface of the tool and die form the final shape of the metal.

Stamping includes a variety of sheet metal forming manufacturing processes, such as punching using a machine press or stamping press, embossing, bending, edging, and coining. Pressing can be a one-step process, where each movement of the press creates the desired shape on the sheet metal part, but stamping can also be carried out in several steps.

Advantages of stamping

Compared to traditional metal cutting and forming methods, metal stamping has many advantages. Here are just a few to consider:

Metal stamping is the fastest method for producing large quantities of components.

After the initial cost of creating the die, metal stamping costs significantly less than other methods.

Metal stamping can create parts with very precise specifications.

All parts produced by metal punching are identical – this is not always the case with traditional methods.

Nordcity Center OÜ’s product range includes DURMA dies with very different functionalities.

IW multifunctional punches – flat and L-profile punching, L-profile cutting, angled and flat cutting and other options depending on the model.

Motorized VN dies – corner punching / cutting

Hydraulic Multi-P 80 punch – for larger punching jobs, this machine is indispensable.

Hydraulic P-NC punch – a large coordinate table makes the operator’s work significantly more accurate, easier and faster.

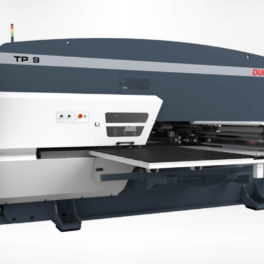

Hydraulic TP punch – a press with significantly higher working speed compared to mechanical presses.

Electric TP Servo die – a more energy-efficient and environmentally friendly die compared to the TP die.

Durma is the world’s leading machine manufacturer and also the world market leader for metalworking machines. The Durma product range covers all the most important areas of metal processing: bending, cutting and processing of profile materials.

Durma exports its products to 82 countries worldwide. The area of the company’s factory premises covers 150,000 square meters and the company employs more than 1,000 employees. Durma works consistently to achieve the highest standards of metalworking equipment.

Take a closer look at our selection of dies and feel free to ask for more information about the equipment if you wish. We are happy to help you find the right device for your business needs.