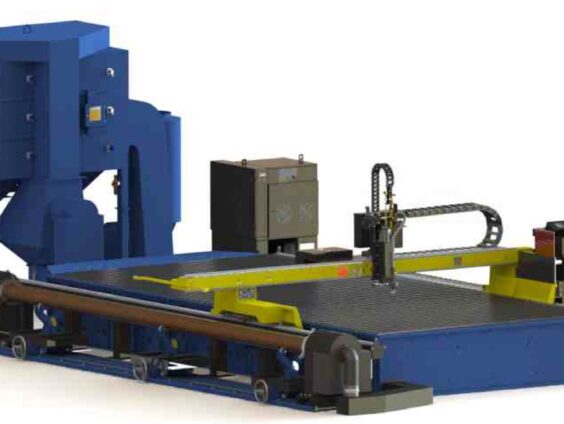

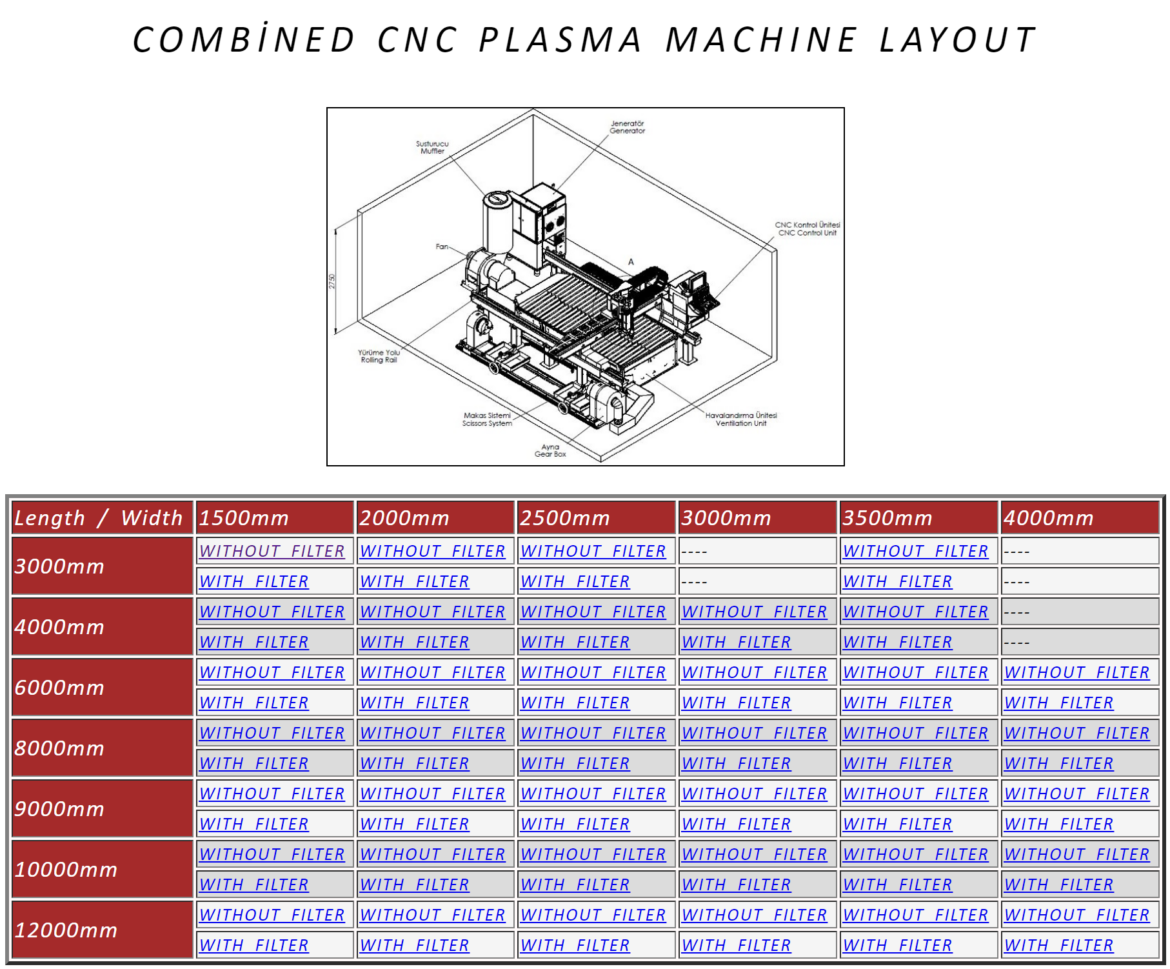

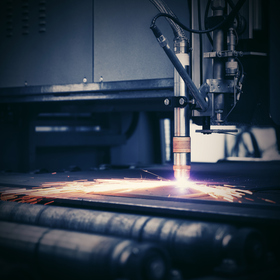

AJAN COMBINED CNC PLASMA CUTTING MACHINES

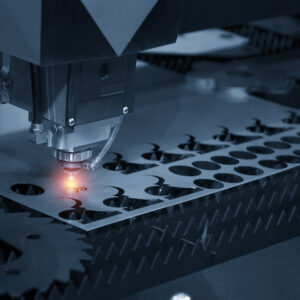

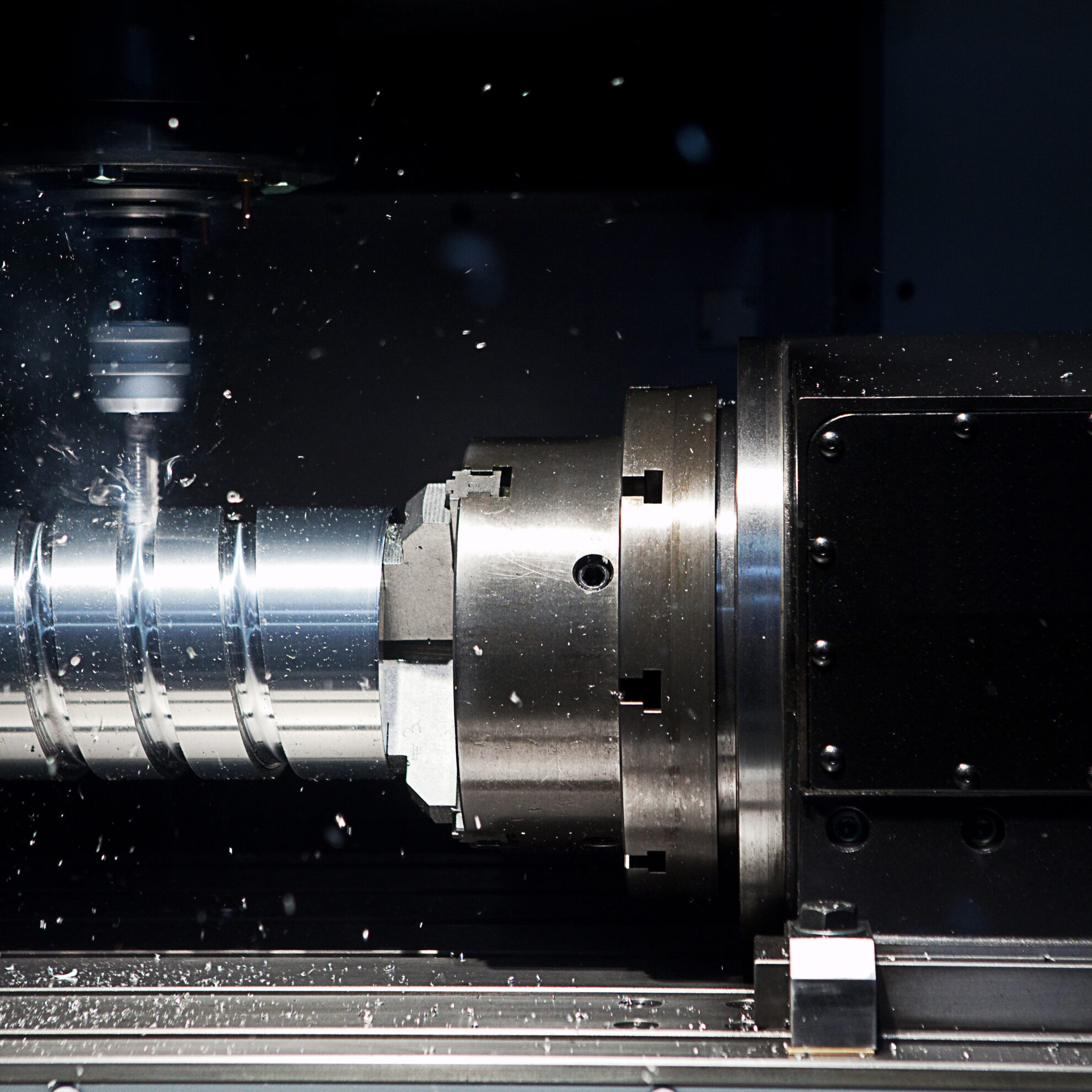

- Ability to cut pipes ranged between 50 and 600mm diameter.

- Steel constructed body.

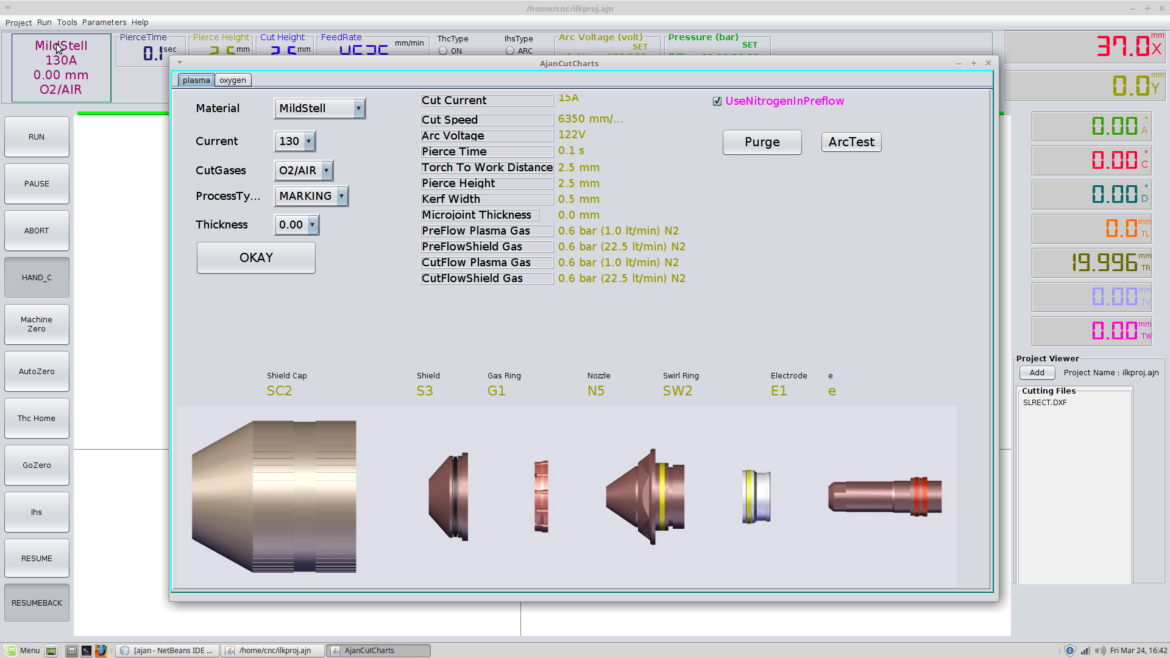

- Precision Plasma 130 / 260 Amper Generator.

- Marking.

- Automatic Torch Height Control.

- Working with standart DIN/ISO G codes ability.

- Ability of working with DXF and NC toolpath files.

- Resume feature.

- Backward contour positioning.

- Automatic Microjoint.

- Nesting Software package

AJAN BKM CNC SERIES has been designed for satisfying the requirements of the user’s to be able to

cut pipes and sheet metal with CNC plasma cutting system. First of all, the most important differences from the

similar machines are that the conventional plasma cutting generator hasn’t been used and it has been

equipped with Precision Plasma series 130 Ampere or 260 Ampere precise cutting plasma generator, torch

and the required gas selections can be made automatically. For that reason, it can cut steel, chrome and

aluminium pipes with high accurancy.

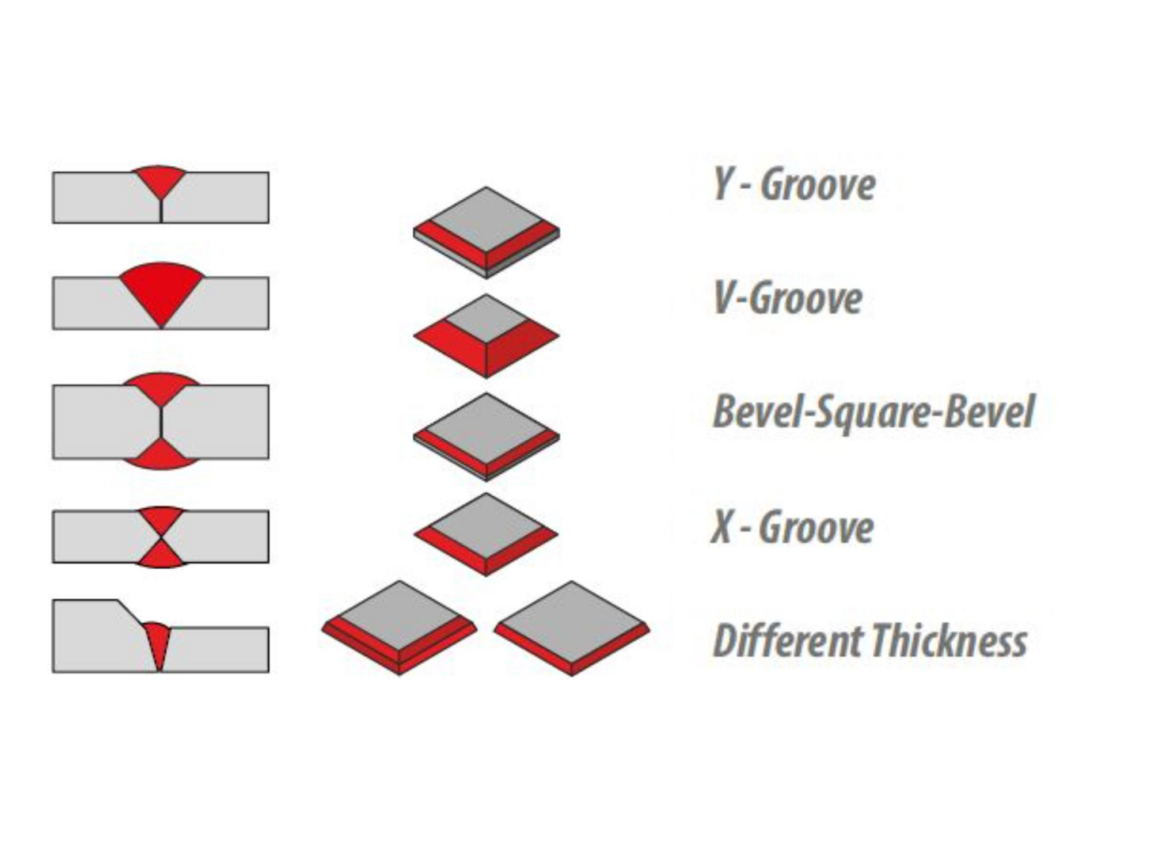

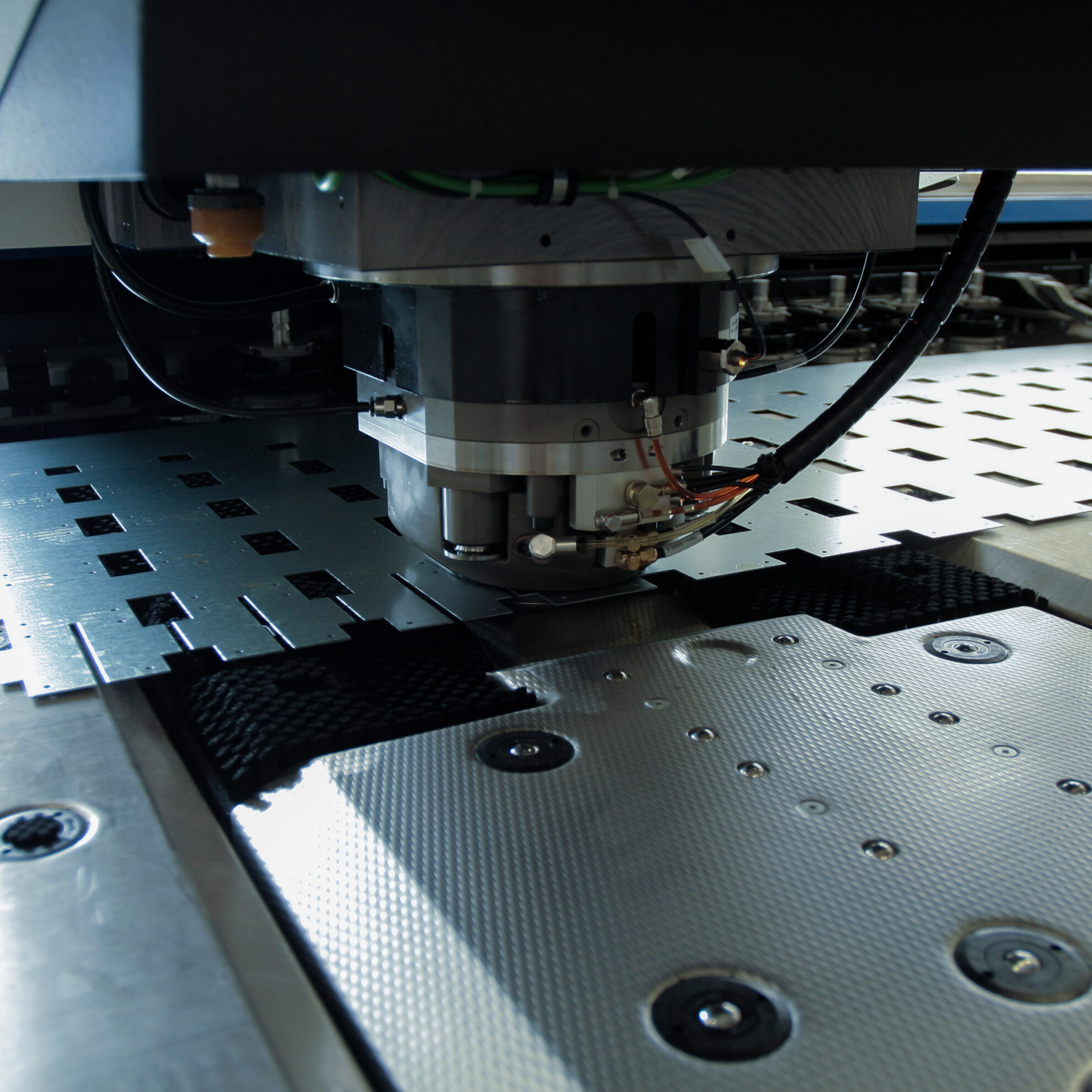

Compact Design

The Worlds Lightest Bevel Head

Full Collision Protection

Beveling Range From 0 to 45° Deg. (0-60° optional)

Maximum Rotation Angle 540°

With One Button Press You Can Change The Cutting From Square to Bevel

Different weld grooves Y – Groove, V-Groove,Bevel-Square-Bevel,

X – Groove, Different Thicknesses

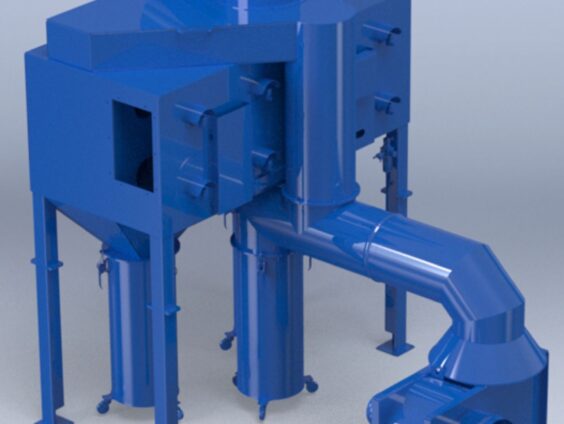

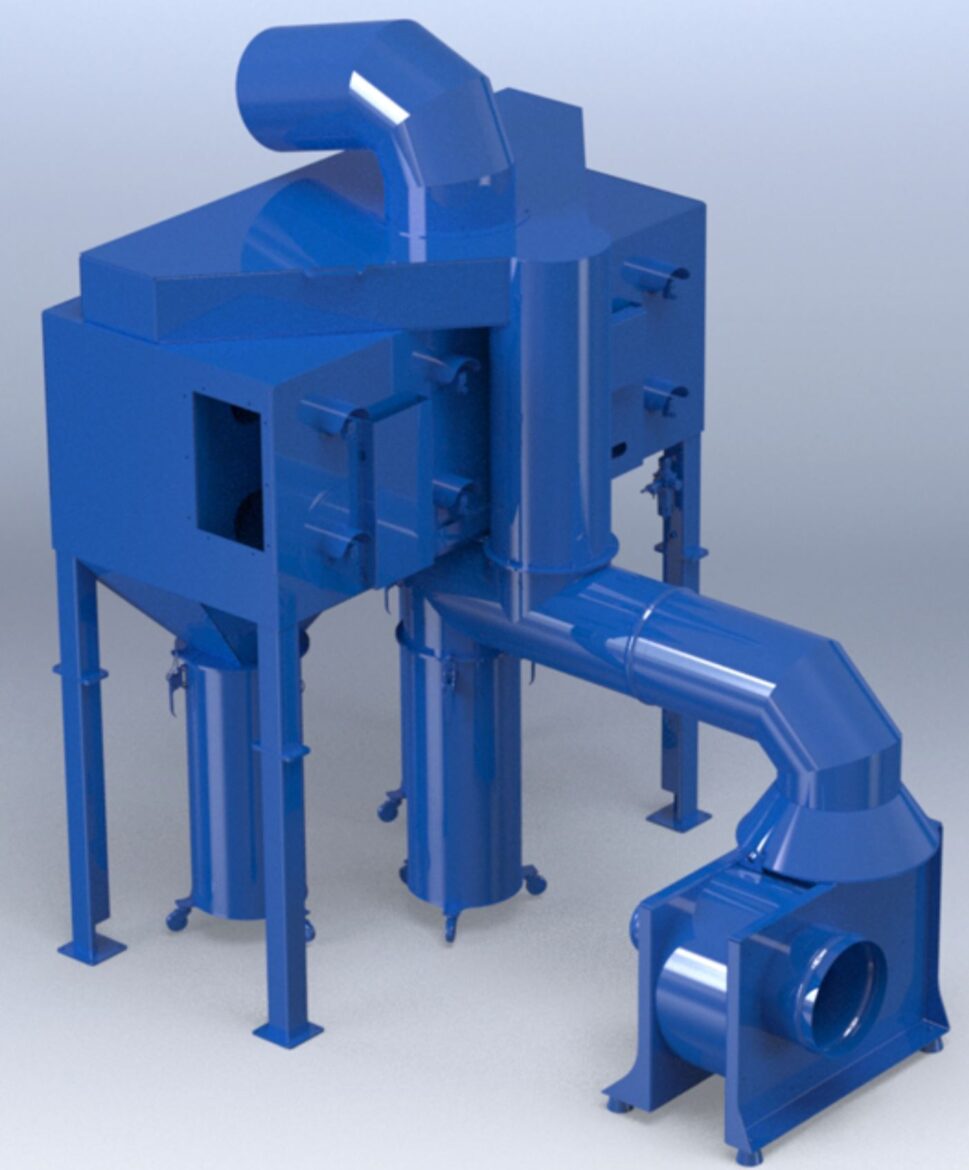

AJANi JUGAFILTRISÜSTEEM

AJANi jugafiltrisüsteem on välja töötatud spetsiaalselt raskete tööstustingimuste jaoks. Pikaajalise teadus- ja arendustöö tulemusena, väiksema õhukulu ning filtri automaatse puhastuse toel on käidukulud miinimumini viidud.

TEHNILISED ANDMED

- Tõhus filtreerimine, üle 99%

- Filtreerimiseks kasutatakse rõhuimpulsse

- Leegikindlad filtrid

- Mahukad peenosakeste kogumisanumad

- Isepuhastusfunktsioon

- Madalad käidukulud

TECHNICAL SPECIFICATIONS

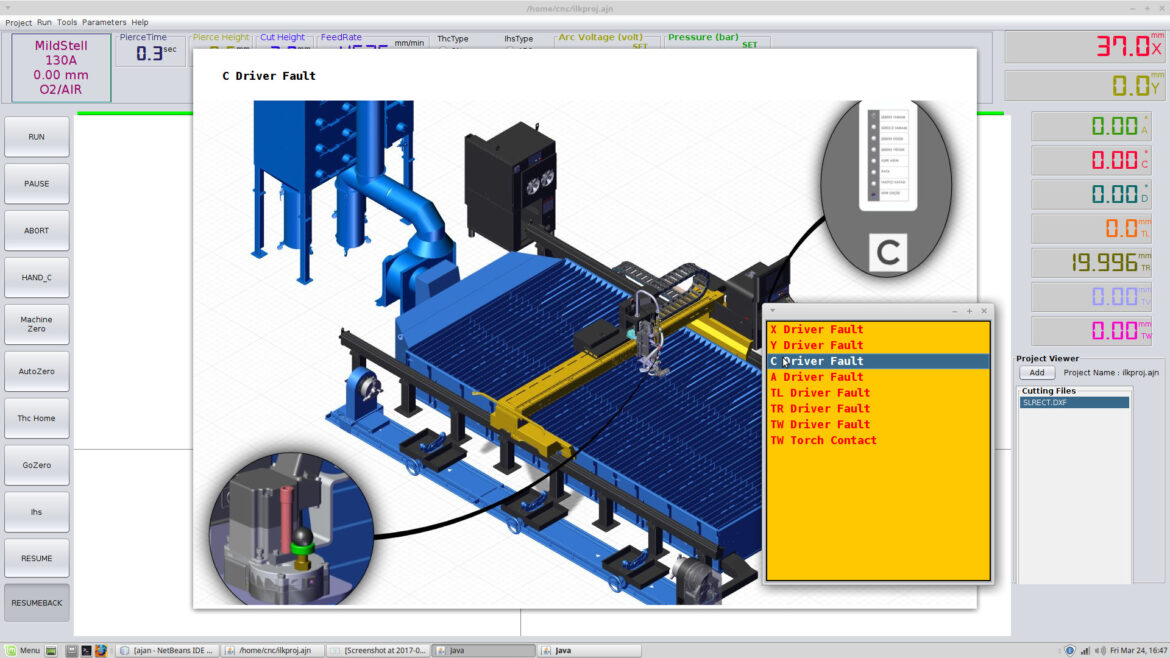

P3 1.2 GHz Cpu.

Motherboard with P3 support.

32 MB VGA Card.

10/100 Mbps Ethernet Card.

USB support.

128 MB Ram PC133 MHz.

10 GB HDD.

17” LCD Monitor.

PS/2 mouse.

Data transfer.

Local area network.

USB Flash Disc.

All inclusive control panel (Dryer, ventilation, generator, jet filter)

Free AJAN CAD program and Geometric Shapes Library.

Automatically cutting resume at break point after electricity shut down.

Working with standard ESSI, ISO, G codes. DXF files.

Leaves kerf width on the program to the cutting process.

Free software updates from the internet.

Language options as; Turkish and English.

Automatically defining the sheet metal angle.

The CNC Unit is made completly in AJAN Company so the client can get all his service

needs, solutions and spare parts directly from AJAN.