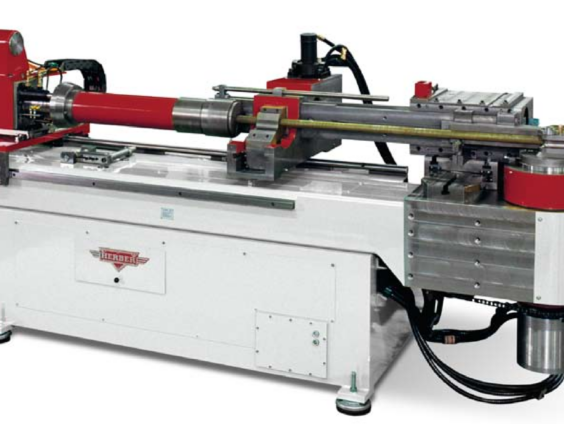

Programmable speed- and pressure setting of the booster unit.

Individually programmable speed and acceleration/retardation

of each axis.

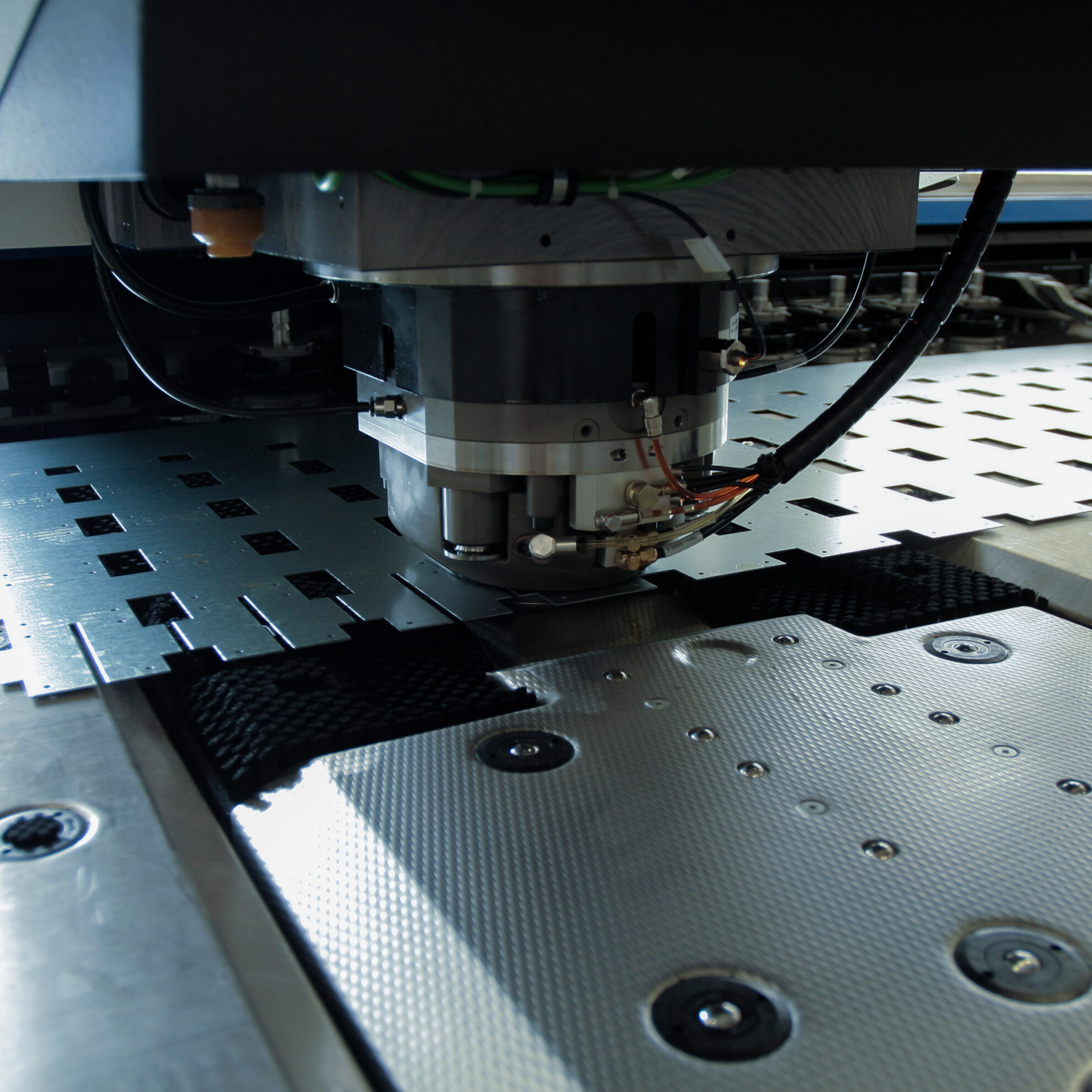

Laser scanner for clamp jaw and pressure die.

Programmable tolerance range of each separate axis.

Standard components from well-known european manufacturers.

Online connection with CAD system or measuring machine.

Customized software.

Macro programming.

Automatic tube magazine with automatic tube loading.

CNC-control system.

The control system works with 4 individually programmable axes.

Bending.

Tube rotation.

Length feeding.

Booster pressure/speed.

The CNC-system is a close loop system which does not allow the machine to continue before previous movement has reached its programmed position. To optimise the accuracy and speed of the machine the degree of tolerance is programmable. Normal programmed tolerance is ±0,05-0,1

mm/degree.

| Technical specifications/Herber 76/90/127 CNC TB | |||

| 76 CNC TB | 90 CNC TB | 127 CNC TB | |

| Capacity, Ø mm | 63 x 5 | 90 x 5 | 127 x 5 |

| Radius, min/max | 40/200 | 50/250 | 80/320 |

| Radius difference | ˗ | ˗ | ˗ |

| Bending speed/repeatability | 40º/s. ±0,1° | 60º/s. ±0,1° | 24º/s. ±0,1° |

| Length of mandrel | 3000 | 4000 | 4000 |

| Weight, kg | 7000 | 10000 | 17000 |

| Machine dimensions | 6,7 x 1,7 x 1,8 | 7,0 x 2,2 x 1,4 | 7,0 x 2,2 x 1,8 |

| Motor kW | 32 | 40 | 40 |

| Length feeding | 900 mm/sec | 900 mm/sec | 900 mm/sec |

| Tolerance range | 0,05–0,1°/mm | 0,05–0,1°/mm | 0,05–0,1°/mm |

| Standard components conform to VDMA, ISO and DIN standards. | |||