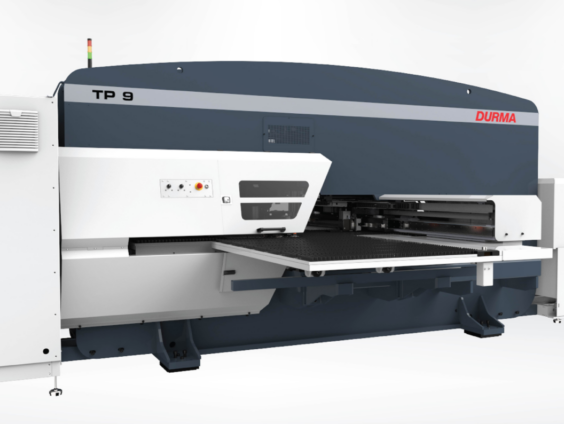

Durma TP SERIES TURRET PUNCH PRESS

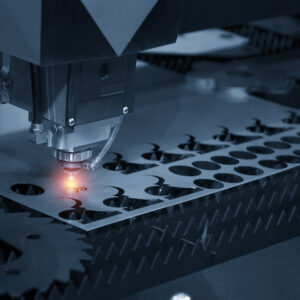

Durma TP Punch Press, offers significantly faster punching speeds than mechanical turrets. The punching head stroke rates of 1200 strokes per minute during punching and 3200 per minute during marking. Also can be forming at punching speed. The machine control adjusts stroke travel speed and position. Simplifies setup of progressive forms, flanges, and embossments.

With roller technology are possible not only on straight geometries but also on curved and round areas. This method is of particular interest for sectors such as air conditioning technology.

TP Series Turret Punch Press today, tomorrow and forever with you.

TP SERIES Turret Punch

- Small, medium and large format sheet processing

- Punching,forming, tapping, and wheel technology capabilities

- Stress relieved O frame

- Flexible turret configurations to eliminate tool setups

- Auto lubrication of moving parts

- Rigid guides

- One of the best controller with functionality & flexibility

- Powerful control with user friendly CAD-CAM Software

- Programmable sheet clamping system decreases set-up times and scrap ratio

- Automation can be easily integrated for efficient and lean operations while also

- Increasing operator safety and as well as decreasing operator fatique

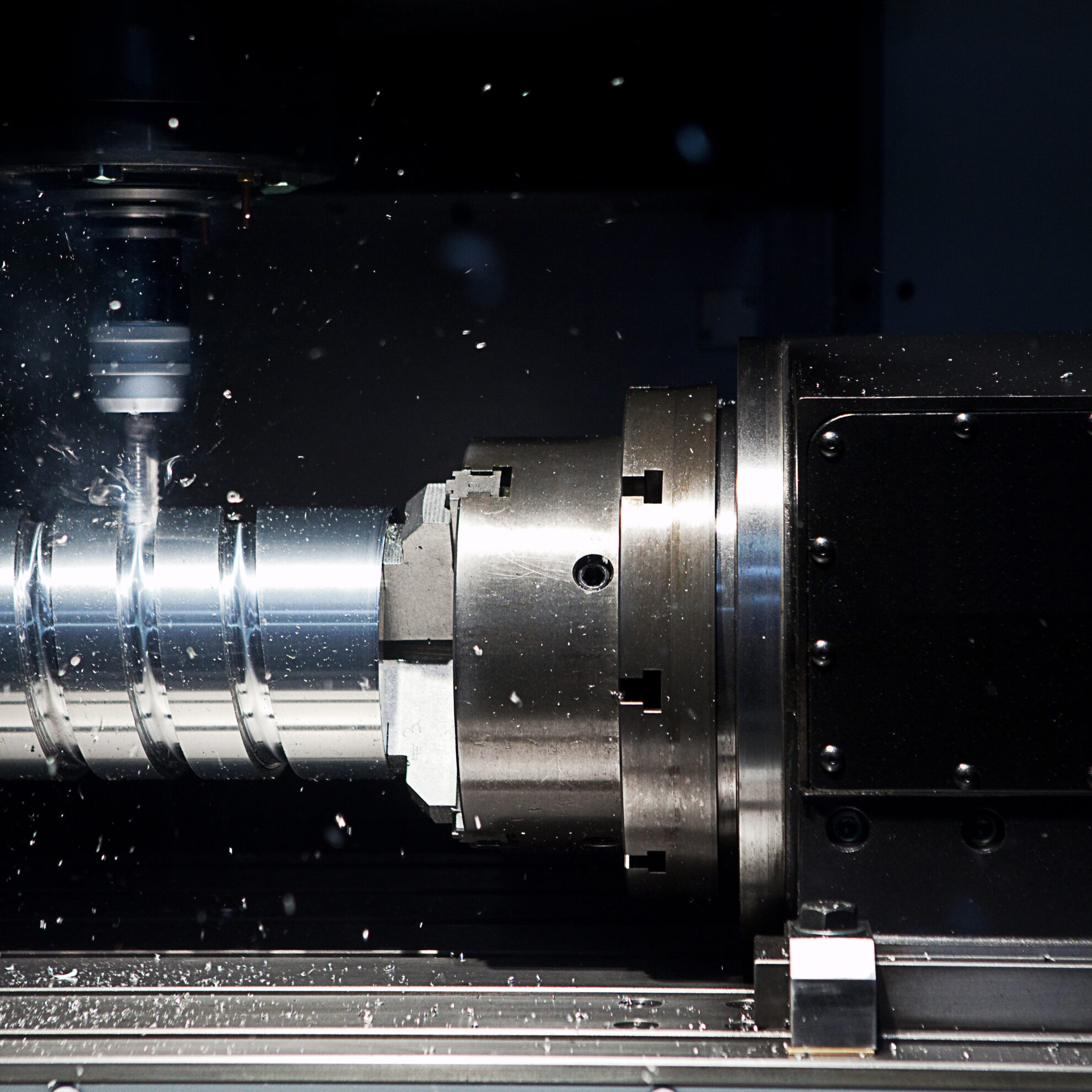

Pre ecise and High Speed Turret

The punching head stroke rates of 1200 strokes per minute during punching and 3200 per minute during marking.

Also can be forming at punching speed. The machine control adjusts stroke travel speed and position.

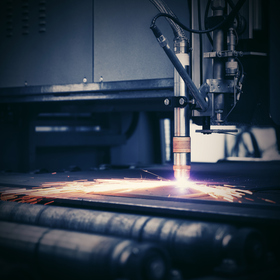

IIntelligent Hydraulics

- Highly dynamic punch drive with closed loop control

- New valve technology DECV: Direct Electronic Copy Valve

- Based on proven Voith H + L copy valve

- Rugged against mechanical stress

- Simple oil filtration is sufficient

- Directly operated, no hydraulic control circuit

- Very fast step response

- Very accurate proportional response

- Predefined machine cycles with programmable stroke parameters

- Process safety by feedback monitoring

- Improved diagnostics by pressure sensors

- Optimized power consumption with load-controlled active “two-pressure-system.

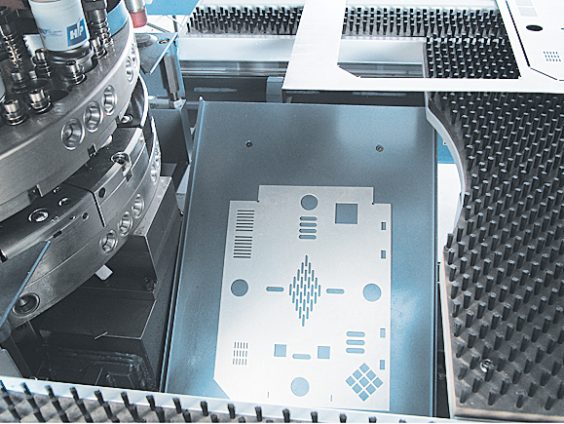

High Quality Forming

Simplifies setup of progressive forms, flanges, and embossments.

With roller technology are possible not only on straight geometries but also on curved and round areas.

This method is of particular interest for sectors such as air conditioning technology.

(Wheel tools, tapping tools) High speed marking

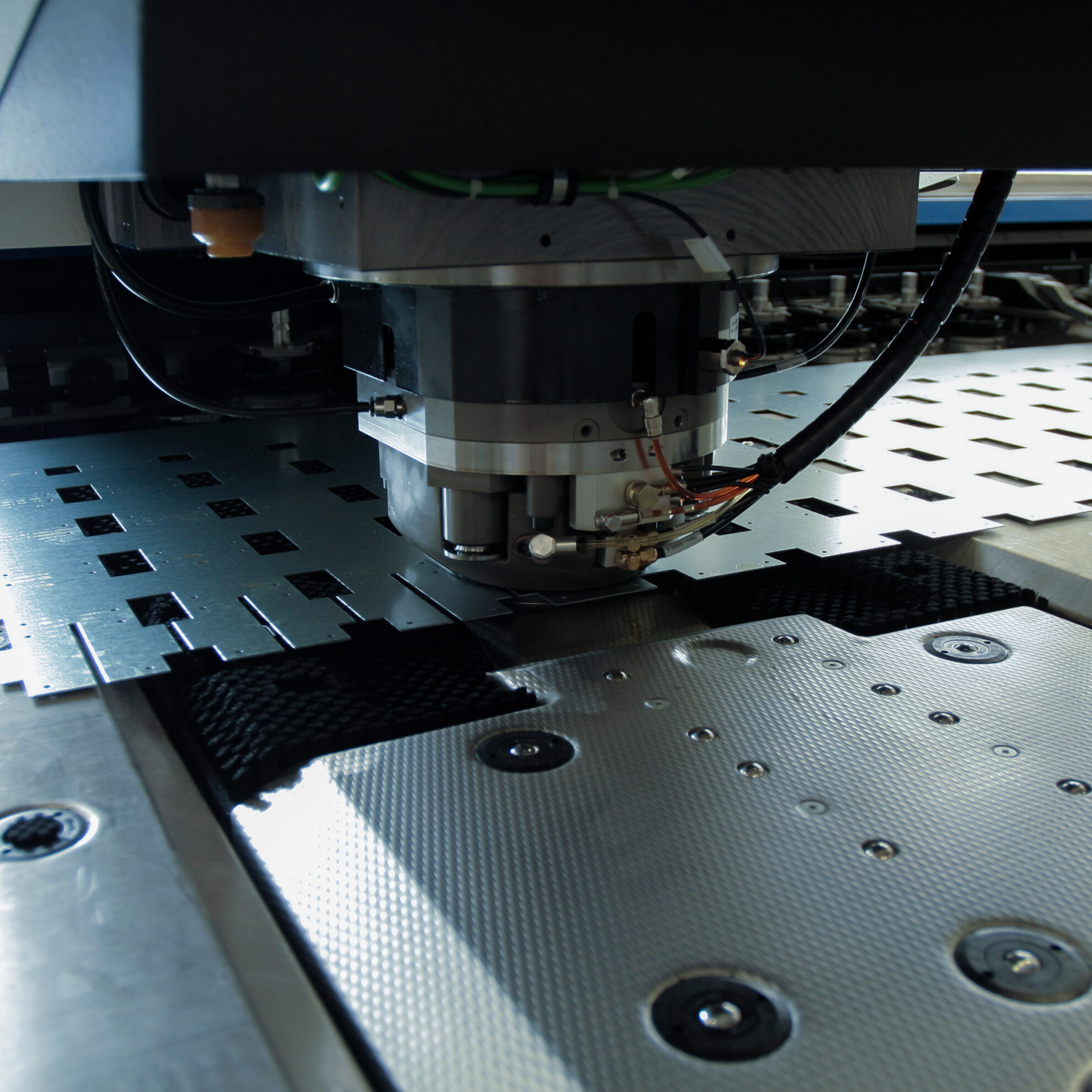

Auto Index Stations

Provide maximum flexibility by simplifying tooling inventories and reducing tool setup time.

Tools are rotatable in 0.01° increments enabling the processing of complex shaped parts with the

minimum number of tools. Tool change takes less than 3 seconds to complete total turret movement

and just 0,6 seconds for single tool.

Reposition

It is possible to process sheet length over table length without need to reposition.

Workchute

To evacuate parts during punching also with sorting and stacking capacity

Motion and Table

A new design of X and Y axis, direct drive technology is used. This will increase the performance and eliminates

any loses from belts, gears or any transmission systems.

Automatic Clamps

When punching thinner material, one of the problem is to control the sheet movement at non clamping area. To

eliminate this matter 3 clamps or more is available.

Cadcam Software

Programming time minimized by using fast and easy CAD-CAM software (cncKAD) metalix. By choosing the

effective position of the tool automatically to use maximum area of the sheet, additional reposition and work strips is

eliminated.

Siemens Sinumerik 840 DSL control system

- Command pedal

- CAD-CAM software & Activator(Dongle)

- Control unit, Siemens Sinumerik 840 D SL Windows 7 operating system

- Remote diagnostic function

- Programming on the control panel

- Automatic clamp positioning.

- Sheet set switches on clamps

- Network, Ethernet communication.

- Automatic tool lubrication

- UPS for control panel

- Movable scrap box

- Brush table

- Oil Cooler

- USB Driver

- Reposition on X axis

- Alignment Tools for Index Stations (C+B Station) – ( for TP6, TP9)

- Alignment Tools for Index Stations (D Station) – (for TP63, TPL63, TP93, TPL93,

- TP123, TP Servo, TPL Servo)

- Manual nesting

- Light barriers for CE

| Technical Details | |||||||

| TP Series | Unit | TP 9 | TP 93 | TP 123 | TPL 93 | TP 123 SERVO | TPL 93 SERVO |

| Maximum tonnage | Ton | 20** | 20** | 30** | 30** | 20** | 20** |

| Frame type | ˗ | O frame | O frame | O frame | O frame | O frame | O frame |

| X axis movement | mm | 2000+ R | 2500+ R | 2500+ R | 3000+ R | 2500+ R | 3000+ R |

| Y axis movement with single tool | mm | 1250 | 1250 | 1250 | 1500 | 1250 | 1500 |

| Automatic Repositioning range * | mm | 10000* | 10000* | 10000* | 10000* | 10000* | 10000* |

| Speed of Y axis | m/min | 70 | 75 | 80 | 60 | 80 | 60 |

| Speed of X axis | m/min | 90 | 100 | 116 | 70 | 116 | 70 |

| Lateral speed Y + X | m/min | 114 | 125 | 140 | 120 | 140 | 92 |

| Max. Hit rate (1mm pitch, 1mm thickness) | 1/min | 1100 | 1100 | 1200 | 1200 | 535 | 535 |

| Max. Hit rate (25mm pitch, 1mm thickness) | 1/min | 375 | 375 | 425 | 325 | 325 | 325 |

| Max. Hit rate : Marking | 1/min | 2800 | 2800 | 3200 | 2800 | 820 | 820 |

| Main cylinder stroke | mm | 40 | 40 | 40 | 40 | 40 | 40 |

| Maximum punching stroke | mm | 25 | 25 | 25 | 25 | 25 | 25 |

| Max. cutting thickness (Fixed Station) | Mild Steel | 6 | 6 | 6 | 6 | 6 | 6 |

| Stainless Steel | 3 | 3 | 3 | 3 | 3 | 3 | |

| Max. cutting thickness (Index Station) | Mild Steel | 3 | 3 | 3 | 3 | 3 | 3 |

| Stainless Steel | 1,5 | 1,5 | 1,5 | 1,5 | 1,5 | 1,5 | |

| Positioning accuracy | mm | ± 0,1 | ± 0,1 | ± 0,1 | ± 0,1 | ± 0,1 | ± 0,1 |

| Repeatable accuracy | mm | ± 0,05 | ± 0,05 | ± 0,05 | ± 0,05 | ± 0,05 | ± 0,05 |

| Turret rotation speed | rpm | 30 | 20 | 20 | 20 | 20 | 20 |

| Auto index rotational speed | rpm | 150 | 150 | 150 | 150 | 150 | 150 |

| Max. weight of sheet | kg | 100 | 120 | 120 | 200 | 120 | 200 |

| Hard disk | Gbyte | 80 | 80 | 80 | 80 | 80 | 80 |

| RAM | Gb SDRAM | 4 | 4 | 4 | 4 | 4 | 4 |

| Network system | ˗ | Windows 7 | Windows 7 | Windows 7 | Windows 7 | Windows 7 | Windows 7 |

| Interactive Flat Panel | inch | 19” | 19” | 19” | 19” | 19” | 19” |

| USB | ˗ | 2 | 2 | 2 | 2 | 2 | 2 |

| Ethernet | 10/100 | 10/100 | 10/100 | 10/100 | 10/100 | 10/100 | |

| Height (H) | mm | 2310 | 2310 | 2310 | 2310 | 2315 | 2310 |

| Width (without light barrier) (W) | mm | 4200 | 5360 | 5360 | 6300 | 5260 | 6160 |

| Width (with light barrier) | mm | 6200 | 7360 | 7360 | 8300 | 6260 | 6260 |

| Length (without light barrier) (L) | mm | 5600 | 5750 | 5750 | 6650 | 5260 | 6210 |

| Length (with light barrier) | mm | 6600 | 6800 | 6800 | 7650 | 6260 | 7210 |

| Table height | mm | 940 | 940 | 940 | 940 | 940 | 940 |

| Weight approx | kg | 11000 | 12960 | 12960 | 18250 | 14000 | 21500 |

| Hydraulic System Motor | kW | 7,5 | 7,5 | 15 | 15 | ˗ | ˗ |

| Oil tank | lt | 180 | 180 | 240 | 180 | ˗ | ˗ |

| Air pressure | bar | 6 | 6 | 6 | 6 | 6 | 6 |

| Number of Clamps | pcs. | 2 | 3 | 3 | 4 | 3 | 4 |

| Holding force of clamps | ˗ | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

| Table type | Brush | Brush | Brush | Brush | Brush | Brush | |

| Energy Consunption | Kw/h | 7,5 | 7,5 | 15 | 15 | 6,21 | 6,21 |

| A – fix 0.8-12.7 mm | Qty | 11 | 11 | 11 | 11 | 11 | 11 |

| B – fix 12.8-31.7 mm | pcs | 10 | 11 | 11 | 11 | 11 | 11 |

| C – fix 31.8-50.8 mm | pcs | 1 | 2 | 2 | 2 | 2 | 2 |

| D – fix 50.9-88.9 mm | pcs | 2 | 1 | 1 | 1 | 1 | 1 |

| B – indeks 12.8-31.7 mm | pcs | 2 | ˗ | ˗ | ˗ | ˗ | ˗ |

| C- indeks 31.8-50.8 mm | pcs | 1 | ˗ | ˗ | ˗ | ˗ | ˗ |

| D- indeks 50.9-88.9 mm | pcs | ˗ | 3 | 3 | 3 | 3 | 3 |

| * : Special table must be added to the machine and the light barriers must be located the correct position. Max.weight 100 kg. | |||||||

| ** : Please pay attention to tool’s spring forces while considering about machine | |||||||

- Additional clamps

- Table (brush&ball)

- Tools, Tool holders, reducers

- CAD-CAM SW Second activator (dongle)

- SW for Autonesting, Wheel and Tapping tools

- Sheet deformation alert switch

- Turret cover for perforated sheets

- Vacuum slug remover

- Workchute

- Automatic lubrication for the machine

- Air condition for electrical box

- Loading- Unloading preparation

- Loading- Unloading system

- Additional table

- Special table

- Transformator

- UPS for machine ( 30KvA – 10 min )

- Additional allignment tool