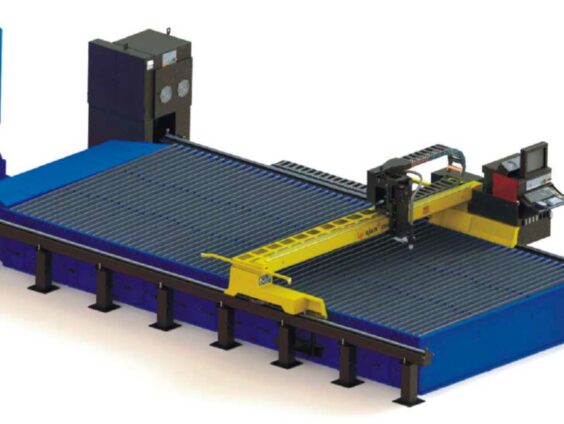

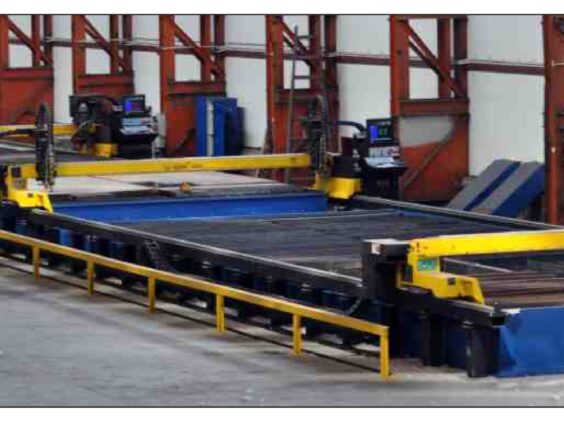

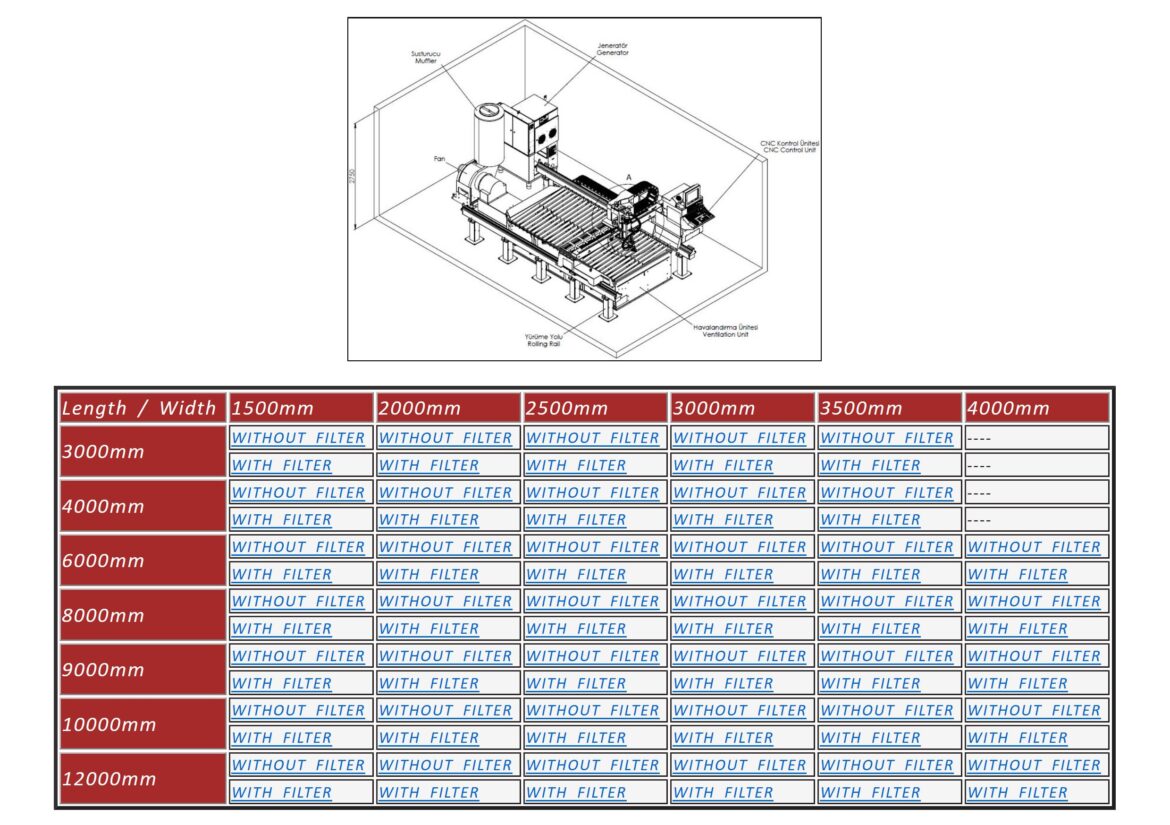

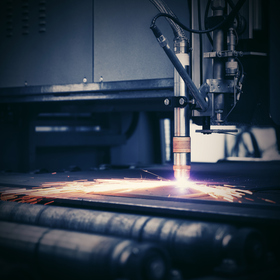

AJAN STANDARD CNC PLASMA CUTTING MACHINES

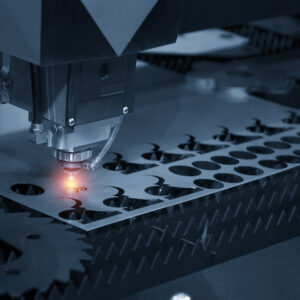

Ajan Electronics produces all machine parts in its own factories; the plasma generator, CNC unit, cutting torch, consumables,servo motors, moving parts, all electronic parts and steel structure,which gives the company a great sales and after sales services advantage.

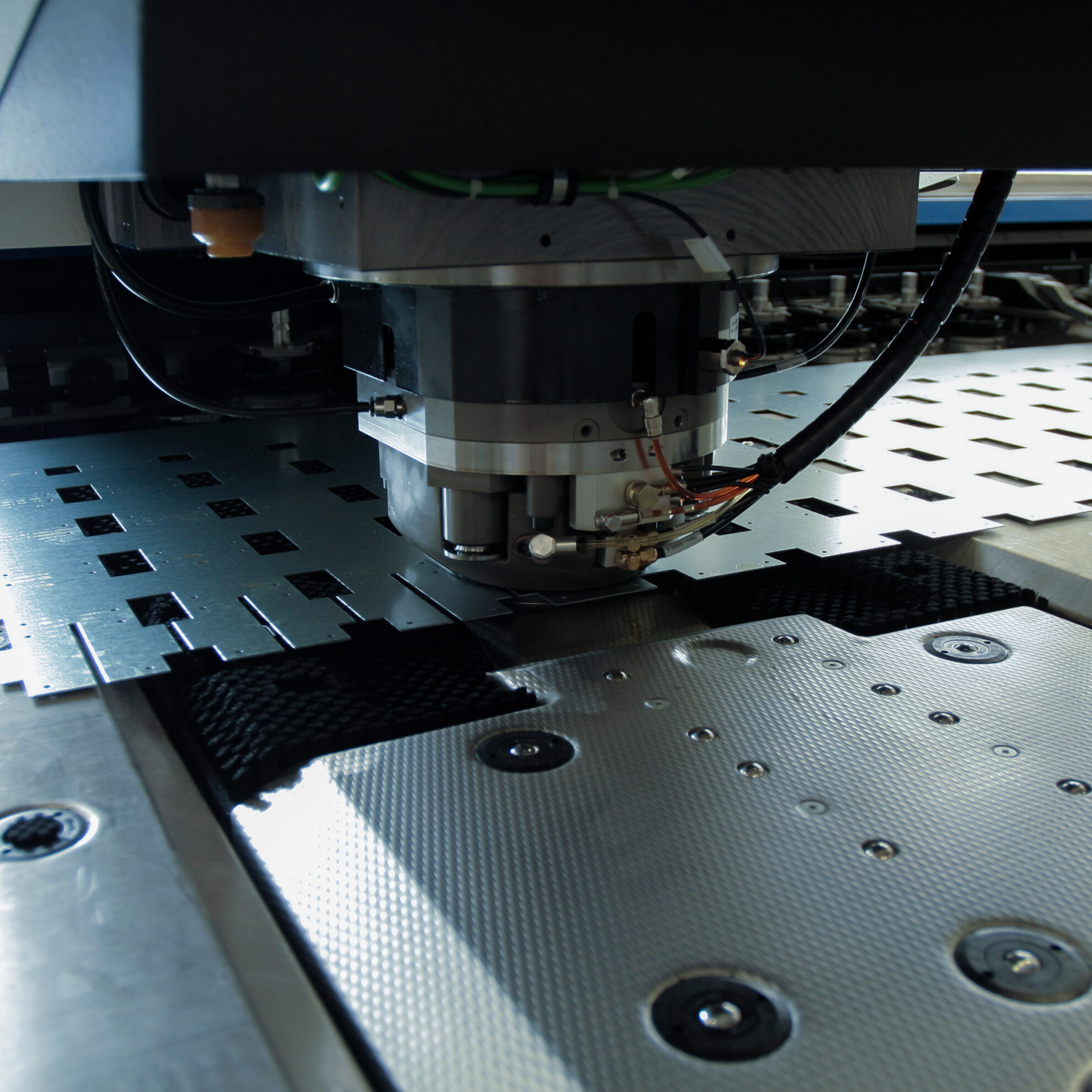

- Microjoint feature (preventing small parts from falling down by connecting them with the main plate through mini bridges)

- Optimizing the hole quality by using the OPTOHOLE technology.

- Automatic sheet metal reference point.

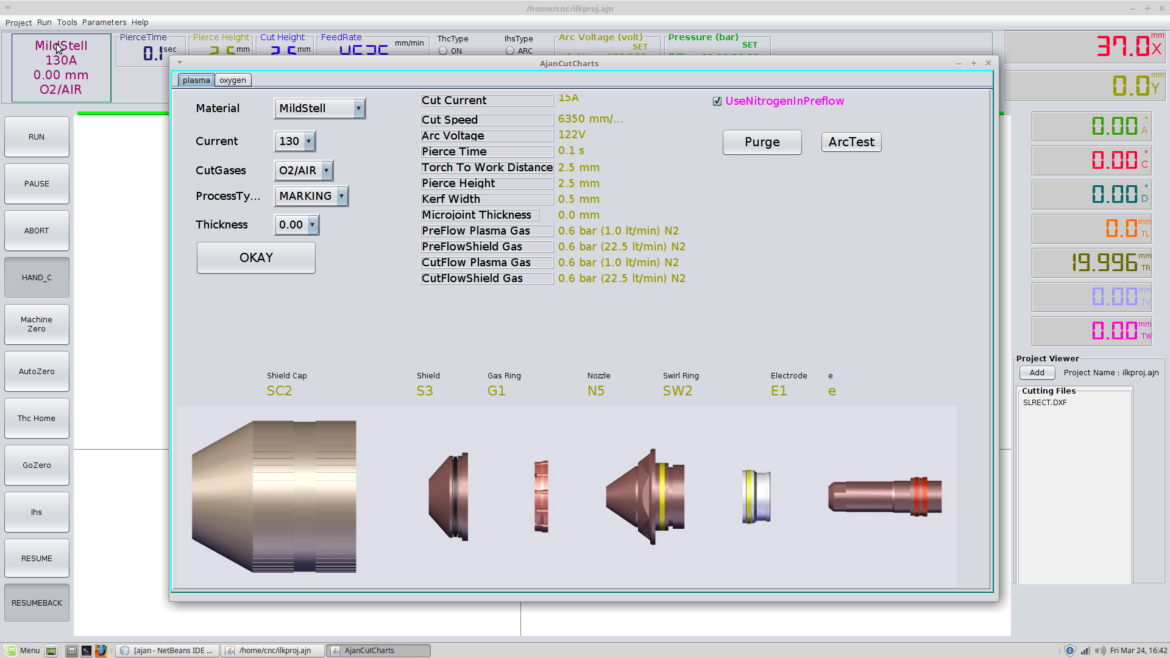

| AJAN PLASMA TECHNICAL SPECIFICATIONS | ||||||

| Material | Amperage | Gas | Min. Thickness | Piercing Thickness | Max. Thickness | Plasma cutting gas consumption (Lt/Min.) |

| Mild Steel | 30 AMP | O2 /O2 | 0.5 mm | 6 mm | 6 mm | 36,5 |

| 40 AMP | O2 /AIR | 2 mm | 6 mm | 6 mm | 4,5 | |

| 80 AMP | O2 /AIR | 2 mm | 15 mm | 20 mm | 10 | |

| 130 AMP | O2 /AIR | 3 mm | 25 mm | 30 mm | 16 | |

| 260 AMP | O2 /AIR | 6 mm | 40 mm | 65 mm | 28,5 | |

| 260 AMP | H35 /N2 | 40 mm | 40 mm | 100 mm | – | |

| Stainless Steel | 45 AMP | N2 /N2 | 0,8 mm | 4 mm | 4 mm | 70 |

| F5 /N2 | 0,8 mm | 6 mm | 6 mm | 9.5 (F5) / 20 (N2) | ||

| 80 AMP | F5 /N2 | 4 mm | 10 mm | 10 mm | 19.5 (F5) / 28 (N2) | |

| AIR /AIR | 3 mm | 10 mm | 10 mm | – | ||

| 130 AMP | N2 /N2 | 6 mm | 15 mm | 20 mm | 78,5 | |

| AIR /AIR | 6 mm | 15 mm | 20 mm | – | ||

| H35 /N2 | 10 mm | 20 mm | 25 mm | 30 (H35) / 48.5 (N2 ) | ||

| 260 AMP | AIR /AIR | 6 mm | 25 mm | 50 mm | – | |

| H35 /N2 | 10 mm | 40 mm | 100 mm | 32 (H35) / 123 (N2) | ||

| Aluminium | 45 AMP | N2 /N2 | 1,2 mm | 4 mm | 6 mm | 52 |

| 130 AMP | AIR /AIR | 6 mm | 20 mm | 25 mm | – | |

| H35 /N2 | 6 mm | 20 mm | 25 mm | 29 (H35) / 40 (N2) | ||

| 260 AMP | AIR /AIR | 6 mm | 25 mm | 100 mm | – | |

| H35 /N2 | 6 mm | 40 mm | 50 mm | 35 (H35 / 114 (N2) | ||

AJAN JET FILTER SYSTEM

Ajan Jet Filter System are specially designed for heavy industry conditions. As a result of long lasting research and development work; with less air consumption and automatic filter cleaning property, the operation costs are reduced to minimum.

TECHNICAL SPECIFICATIONS

- Efficient filtering, more than 99%

- Filtering is done, by applying pulse pressure

- Flame resistant filters

- High volume particles collecting buckets

- Self cleaning feature

- Low operation costs

TEHNILISED ANDMED

P3 1,2 GHz CPU

Emaplaat P3 toega

32 MB VGA graafikakaart

10/100 Mbps Etherneti kaart

USB tugi

128 MB RAM PC133 MHz

10 GB HDD

17” LCD kuvar

PS/2 hiir

Andmete ülekanne

Kohtvõrk

USB mälupulk

Keskne juhtpaneel (kuivati, ventilatsioon, generaator, jugafilter).

Tasuta AJANi CAD-programm ja geomeetriliste kujude andmebaas.

Automaatne lõikamise jätkamine katkestuspunktis voolukatkestuse järel.

Töö standardite ESSI, ISO, G koodidega. DXF failid.

Lõikelaius jääb programmi lõikeprotsessi jaoks.

Tasuta tarkvarauuendused internetist.

Keelevariandid

Lehtmetalli nurga automaatne määramine.

Arvjuhtimisüksus on valmistatud täielikult AJANi poolt, seega saab klient kogu vajaliku hoolduse, lahendused ja varuosad AJANilt.

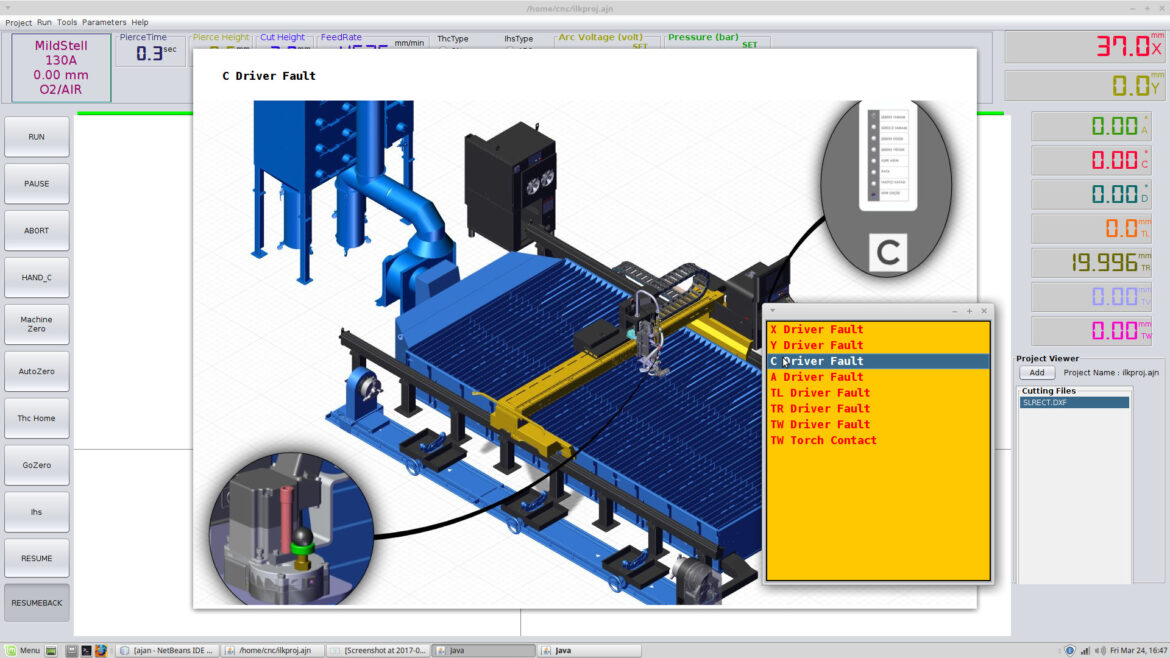

All inclusive control panel (Dryer, ventilation, generator, jet filter)

Free AJAN CAD program and Geometric Shapes Library.

Automatically cutting resume at break point after electricity shut down.

Working with standard ESSI, ISO, G codes. DXF files.

Leaves kerf width on the program to the cutting process.

Free software updates from the internet.

Language options as; Turkish and English.

Automatically defining the sheet metal angle.

The CNC Unit is made completly in AJAN Company so the client can get all his service

needs, solutions and spare parts directly from AJAN.