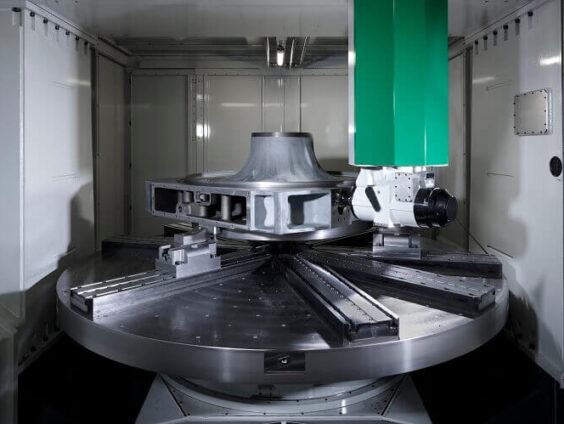

UNICOM7000-XL Large Vertical machining and turning center

4 m Y-axis

4 m diameter

Big advantages This extra large capacity machining solution for turning and milling really big parts offers more clearance in the Y-axis and can be stepped up in the X-axis to 5 metres. Like the Unicom 7000, this multi-task portal machine manages to deliver high output without sacrificing accuracy or quality. The standard configuration includes a vertical carousel turning station, head changer and pallet changer for big pallet sizes. With less handling and fewer setups lead times are shorter, boosting productivity of extra large work pieces.

Bigger is better

With a multi-task machining centre, extremely large components can be finished on the one machine. This cuts down handling time and results in shorter lead times. The Unicom 7000-XL is a highly adaptable and functional machine that removes large quantities of steel very quickly. Its pallet loading stations allow setup to take place during the machining cycle, which raises productivity even further.

Reliable processing

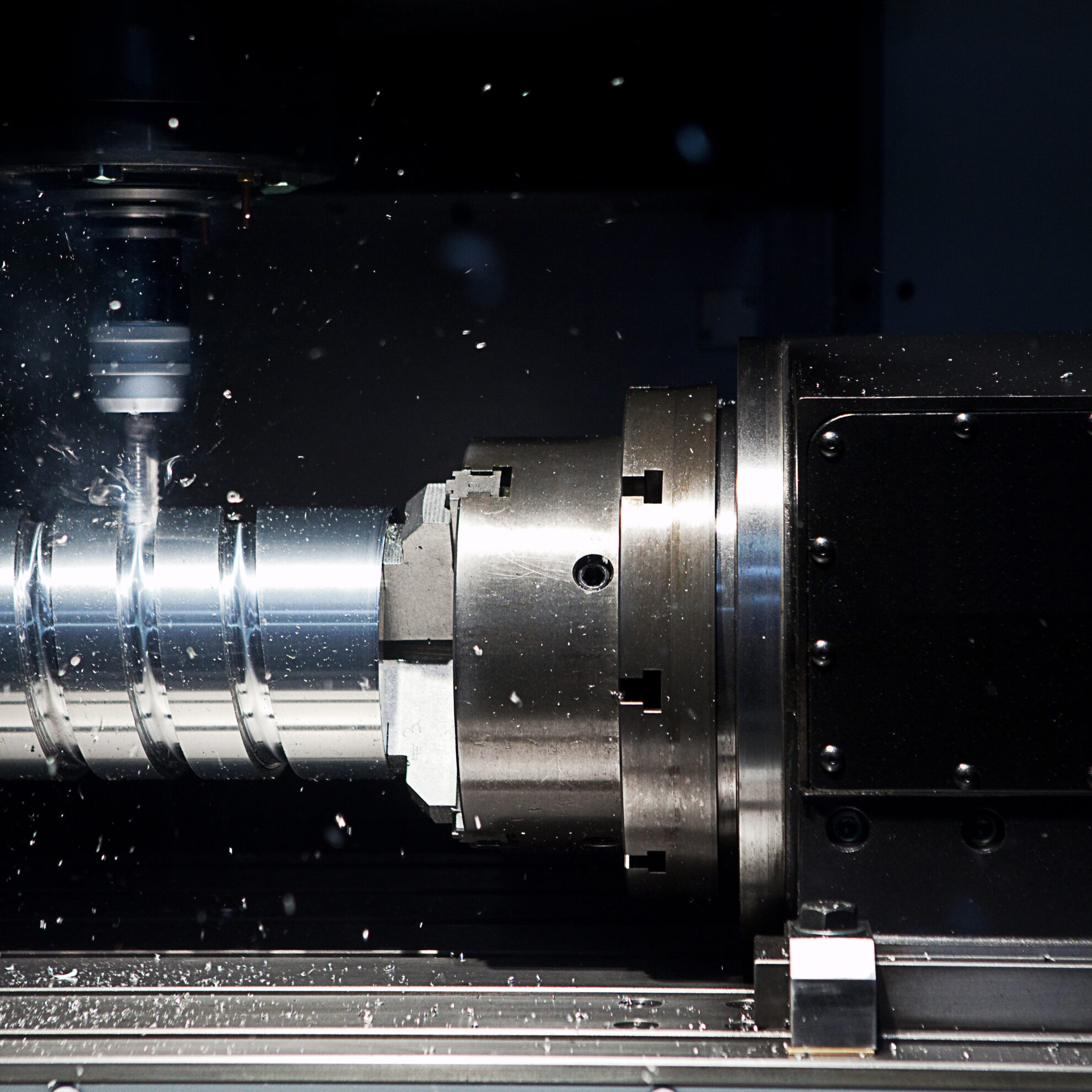

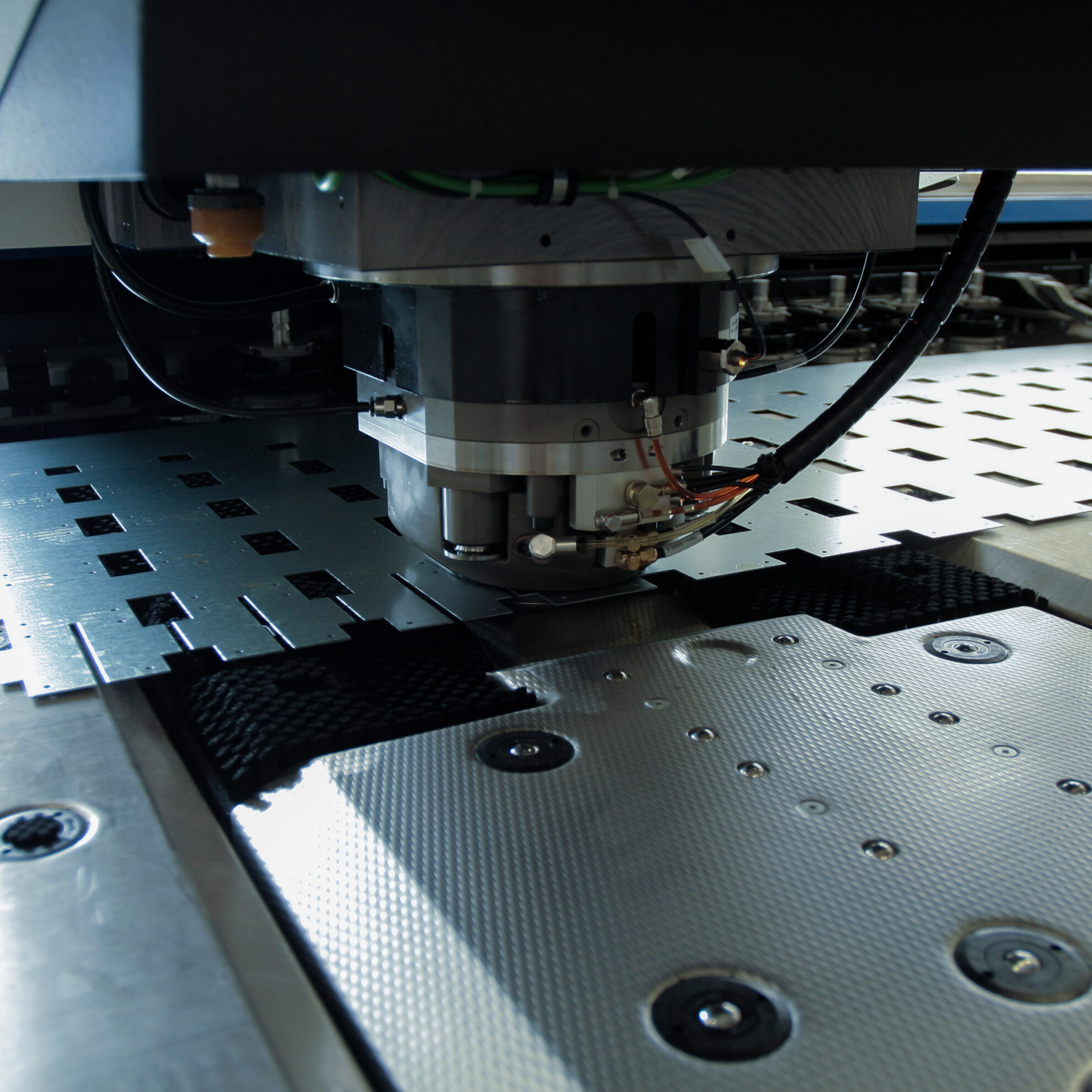

With its two-stage gearbox drive for milling and turning, the Unicom 7000-XL achieves high torque and high rotational speed. The machine’s ram with its turning tool adapter allows ‘plunging’ into the part as well as the use of short, stable tools. And the in-process measuring probe, which ensures reliable processing of tight fits, saves time.

Repeatable accuracy

The Unicom 7000-XL has an in-process measuring probe, which functions without needing a tool change. This also means that repeatability of the setup station can be guaranteed to a few microns. What’s more, even higher accuracies in end products are achieved since there are fewer machining setups to start with. For convenience, there is just one tooling system in the whole machine for the turning and milling operations. And for safety, there’s a fully enclosed cabin.

Pallet changer

Right angular indexing head

Universal indexing head

5-axes configuration

In-process measuring

| Work area | |

| X-axis | 3.500 – 5.000 mm |

| Y-axis | 2.500 – 4.000 mm |

| Z-axis | 1.600 mm |

| Vertical clearance | 2.000 / 2.300 mm |

| Table | |

| Table size | 2.000 – 4.000 ø mm |

| Swing circle | 3.000 – 4.500 ø mm |

| Spindle | |

| Gear box driven spindle and values | 42 Kw |

| 6.000 min-1 | |

| 1.600 Nm | |

| Carousel turning station | 70 / 95 kW |

| 33.000 / 70.000 Nm | |

| Various | |

| Tooling | |

| Taper size | HSK100A / Capto C8 |

| Number of pockets | # 97 – 200 |

| Tool change time | 10 sec |

| Speed | |

| Rapid traverse | 40.000 mm/min |

| Feed Rate | 5-40.000 mm/min |