UNISIGN UNIPORT 7000-MTC Multi Task CNC Machining Centre

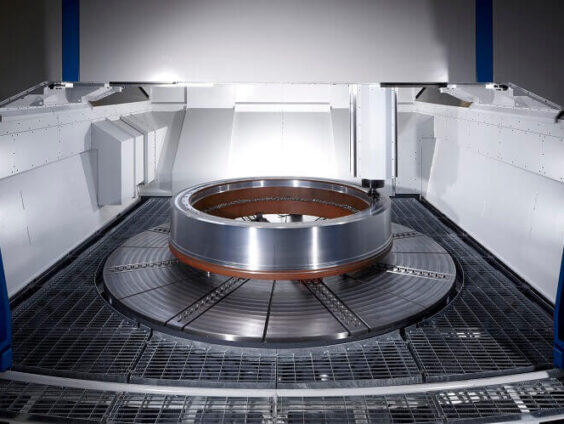

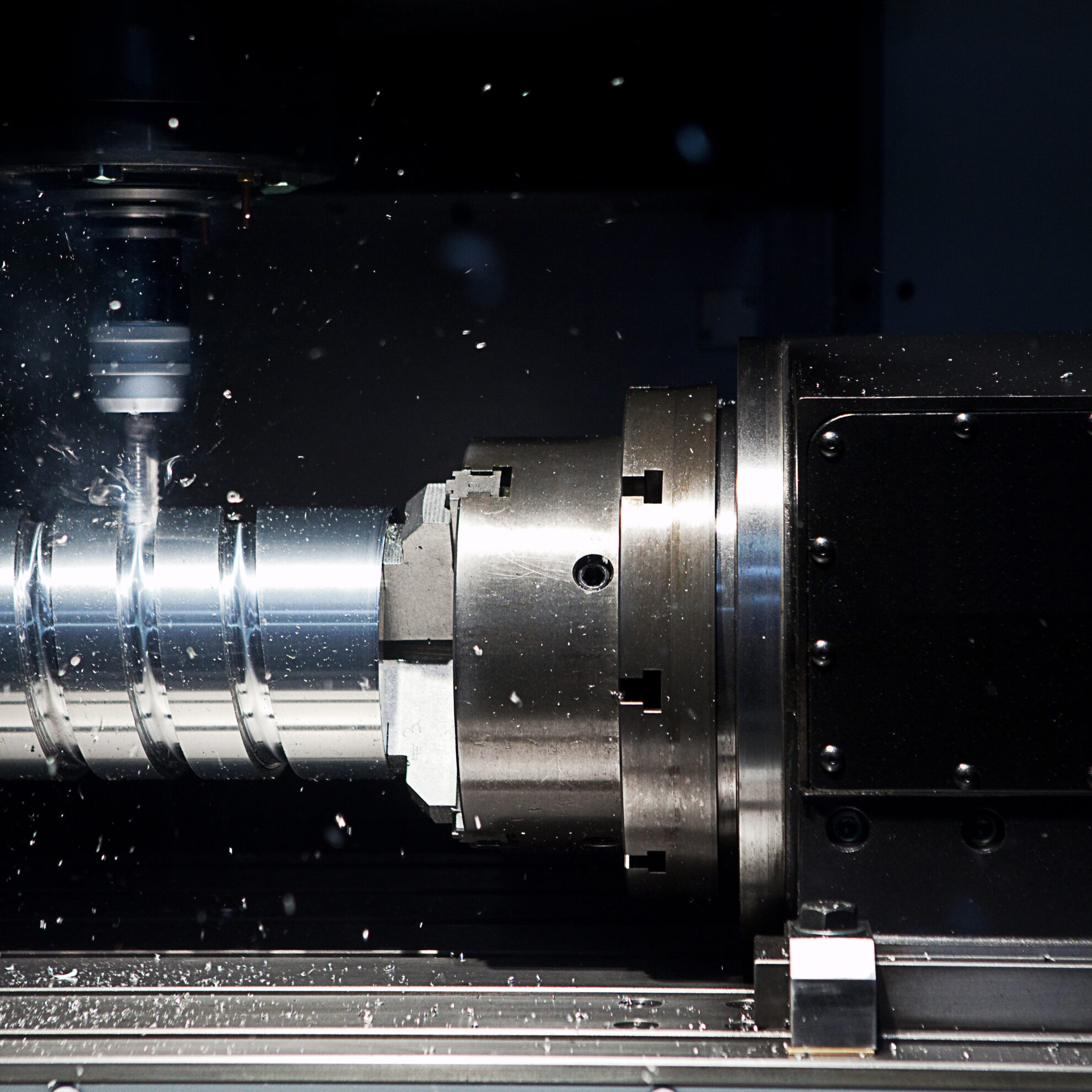

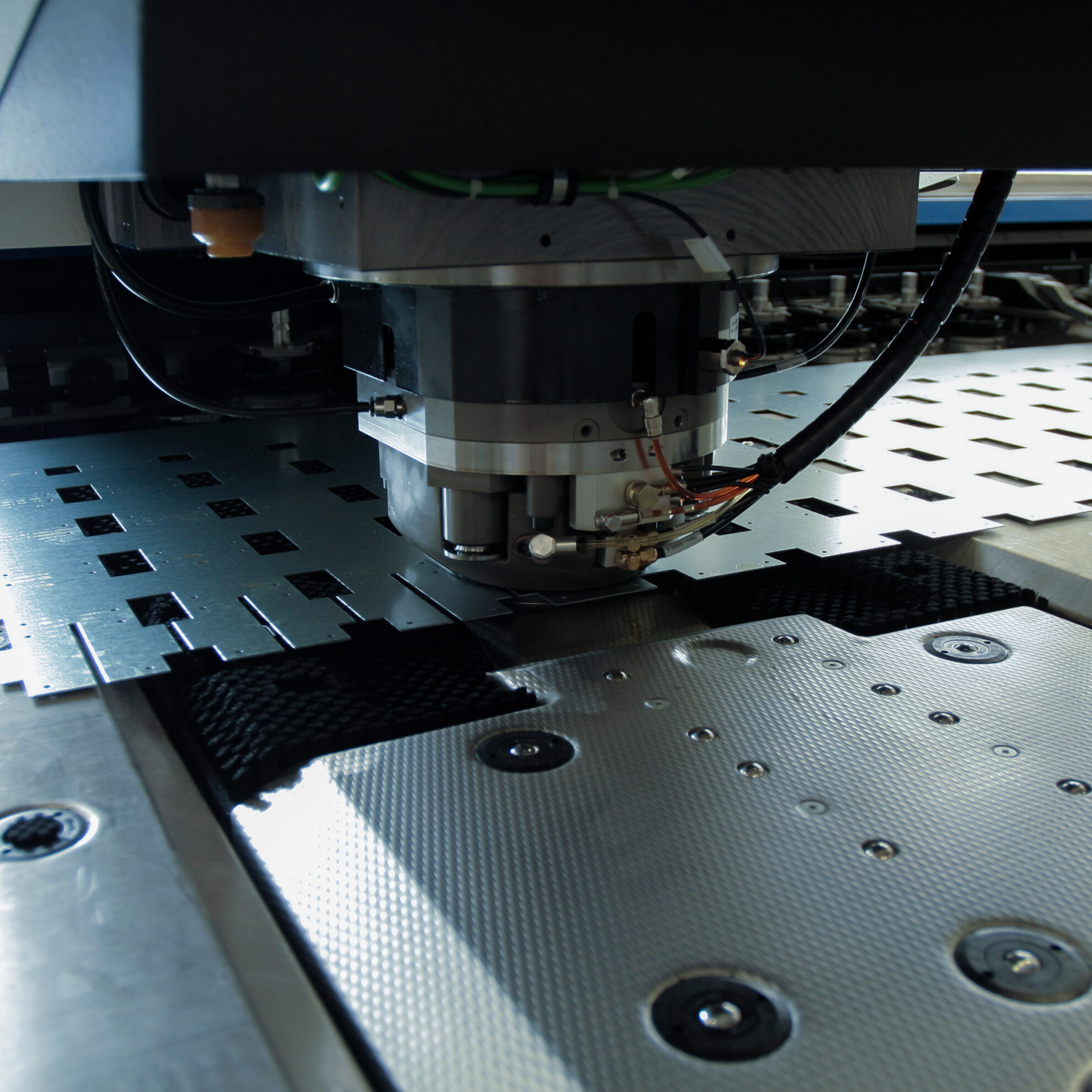

Short lead times When you need the flexibility of mill-turn operations on both single part and series production, choose the Uniport 7000-MTC. This multi-task machine achieves extremely short lead times and very high accuracy, and is ideal for quick-response manufacturing. A high-rail gantry machine with a travelling bridge and stationary carousel turning station, it is built on our most flexible machine platform. It will perform 5-axis machining within a large working envelope, making it a truly cost-effective production choice for a wide range of applications. The innovative ‘box-in-box’ construction guarantees superb rigidity and very stable and accurate production processes.

One to the power of two

With a Unisign multi-tasking machine you effectively get two machines in one, reducing your capital investment. For such machines, flexibility and reliability go hand in hand with productivity. The wide choice of spindles, drive units and machining heads that comes with the Uniport 7000-MTC extends its capabilities enormously. And with features like a dedicated exchangeable head for turning tools that eliminates load on the bearings while turning, you can be assured of a longer machine life too.

High capacity

With its dedicated high-torque turning station, the Uniport 7000-MTC has enormous capacity, even for large diameter components. It can also take a very high load – up to 80 Ton on a 4.5 metre table – so that very heavy parts can be machined. And with the extended portal height of up to 2.6 meters, tall parts can also be handled with equal ease.

Quick changeovers

Good accessibility, with the table at floor level, means it’s easy for operators to step onto the table to change clamps and work pieces. And that enables really quick changeovers! It’s fully enclosed too, which not only keeps the working environment clean but also ensures a high level of safety.

Right angular indexing head

Universal indexing head

Various turning tool adaptors

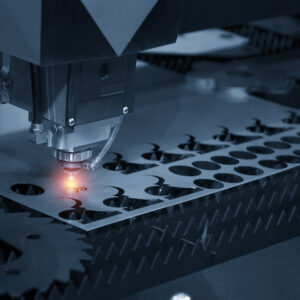

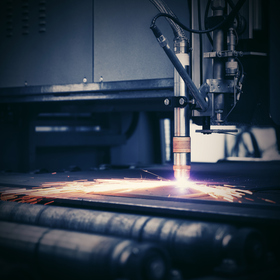

5-axes machining

In-process measuring

| Work area | |

| X-axis | 3.000-6.500 mm |

| Y-axis | 2.000 – 3.500 mm |

| Z-axis | 1600 mm |

| Distance spindle nose to table | 500 – 2.100 mm |

| Table | |

| Table size | 2.000-6.000 ø mm |

| Swing circle | 2.500 – 6.500 ø mm |

| Spindle | |

| Gear box driven spindle and values | 42/73 kW |

| 6.000 min-1 | |

| 1.600 Nm | |

| Carousel turning station | 95 kW |

| up to 135.000 Nm | |

| Various | |

| Tooling | |

| Taper size | HSK100A / Capto C8 |

| Number of pockets | # 52 – 206 |

| Tool change time | 10 sec |

| Speed | |

| Rapid traverse | 40.000 mm/min |

| Feed Rate | 5 – 40.000 mm/min |