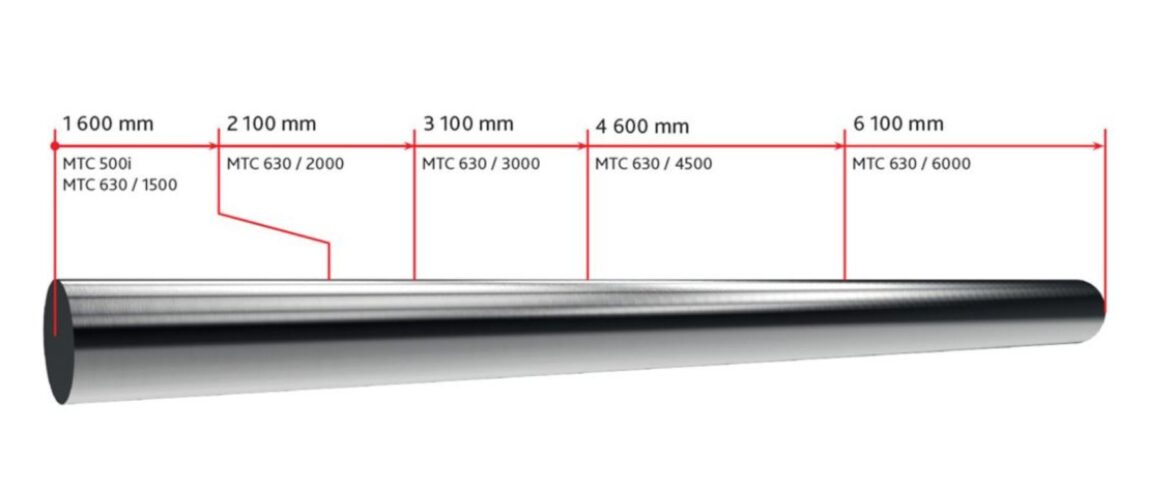

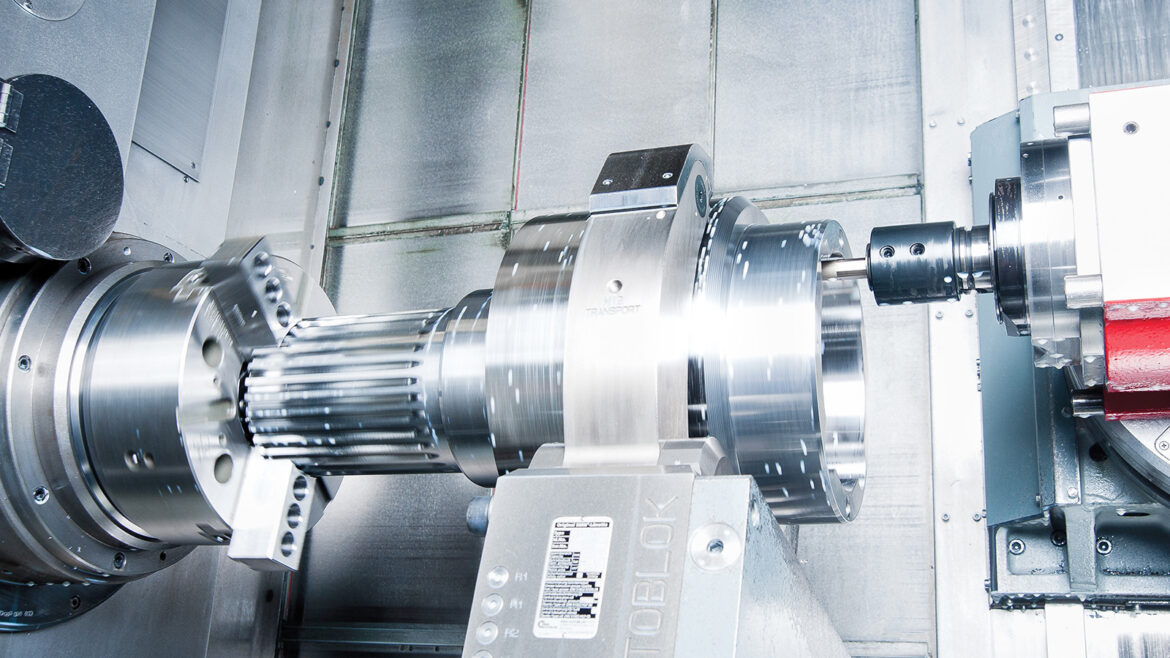

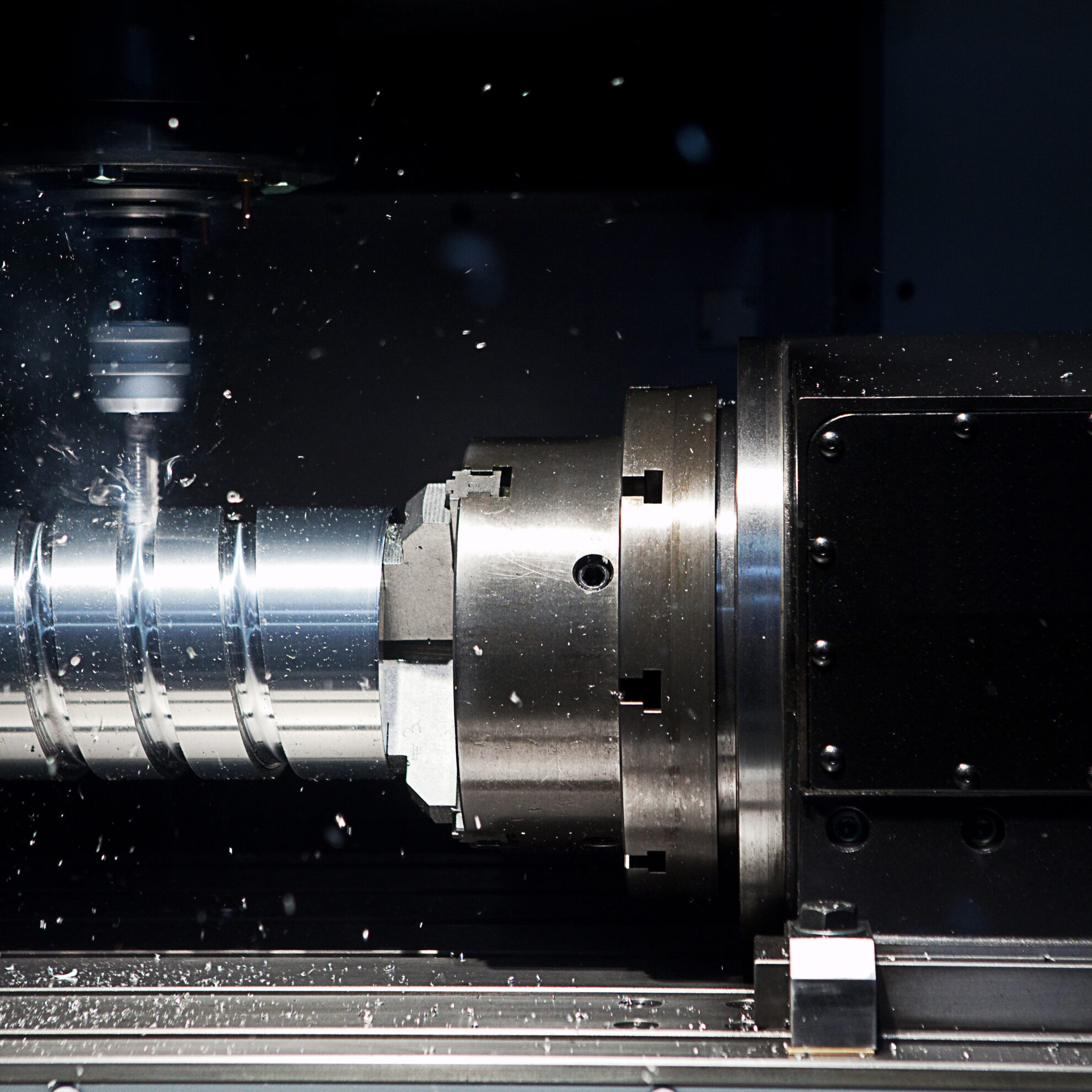

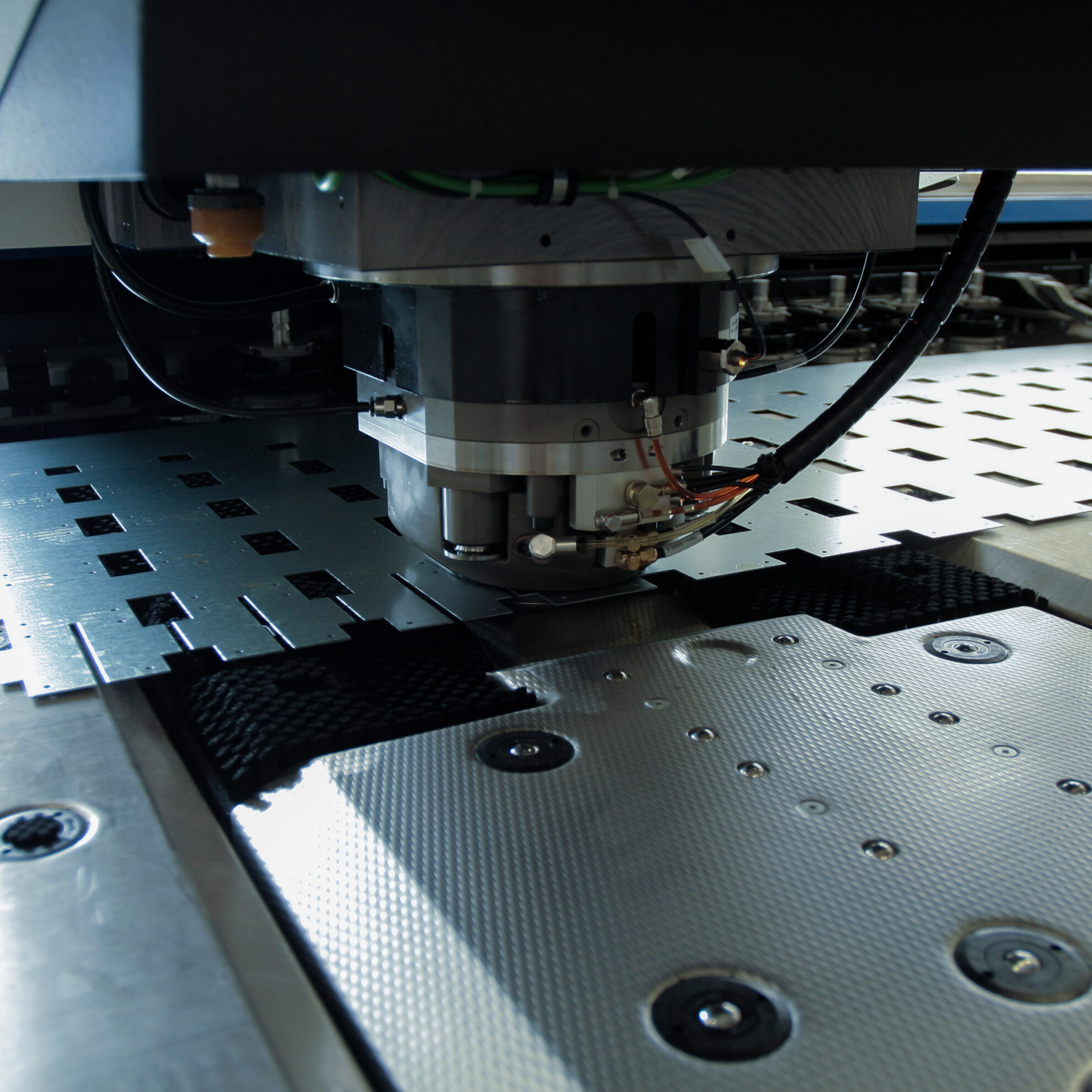

KOVOSVIT MULTICUT 500i Multi-tasking turning milling machining center

Max. turning dia: 1 030 mm

Max. turning length: 1 734 mm

Max. Workpiece weight: 3 000 Kg

Max.output S1 / S6 – 40%: 59 / 72 kW

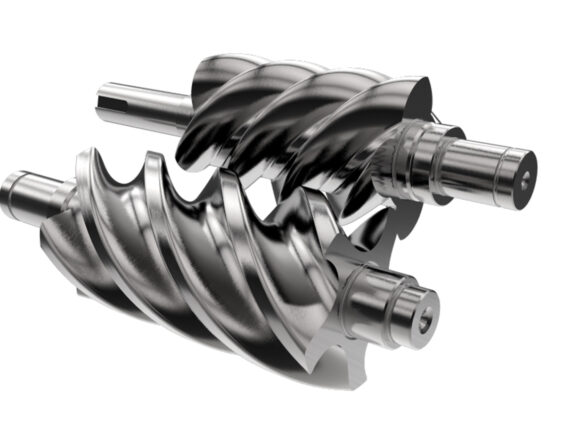

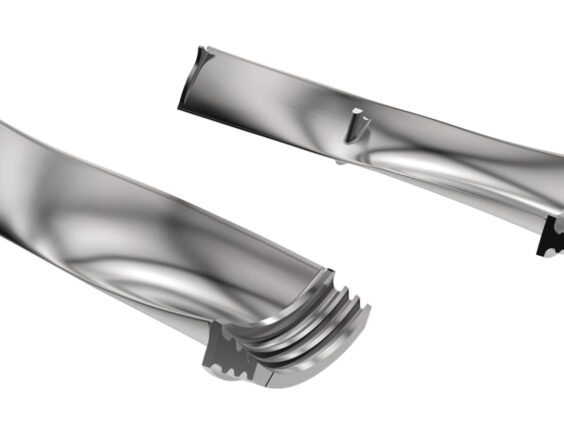

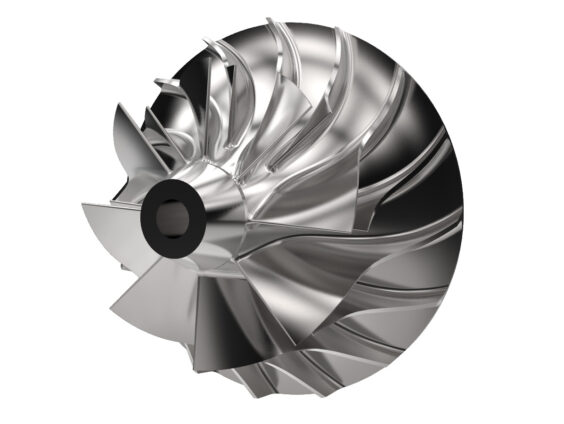

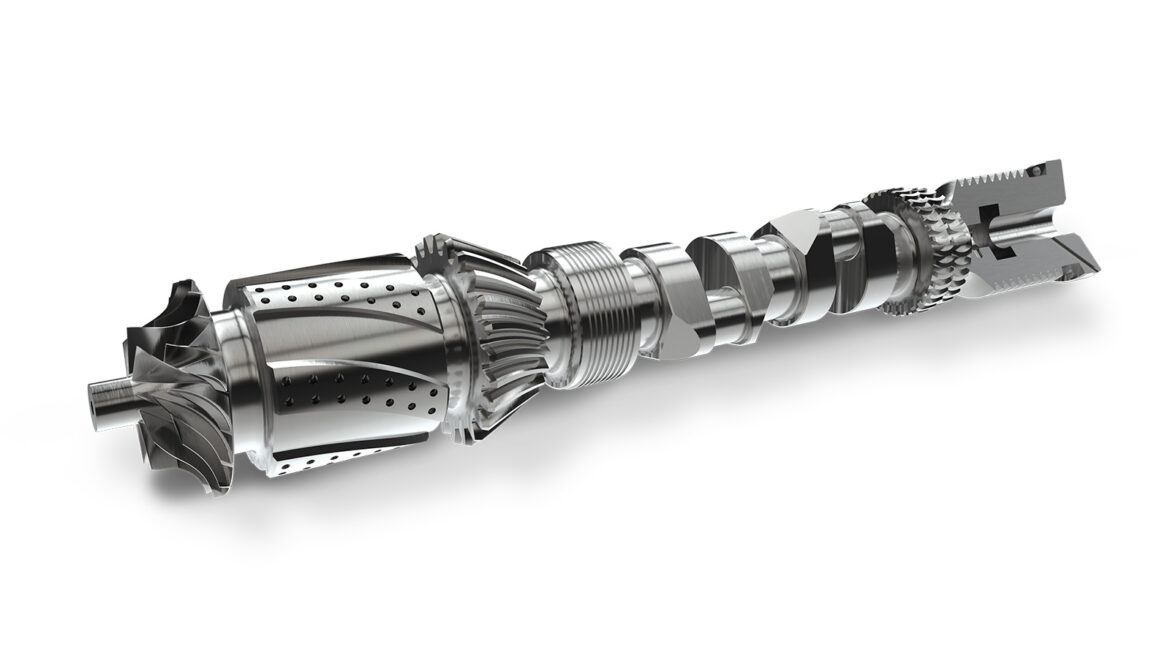

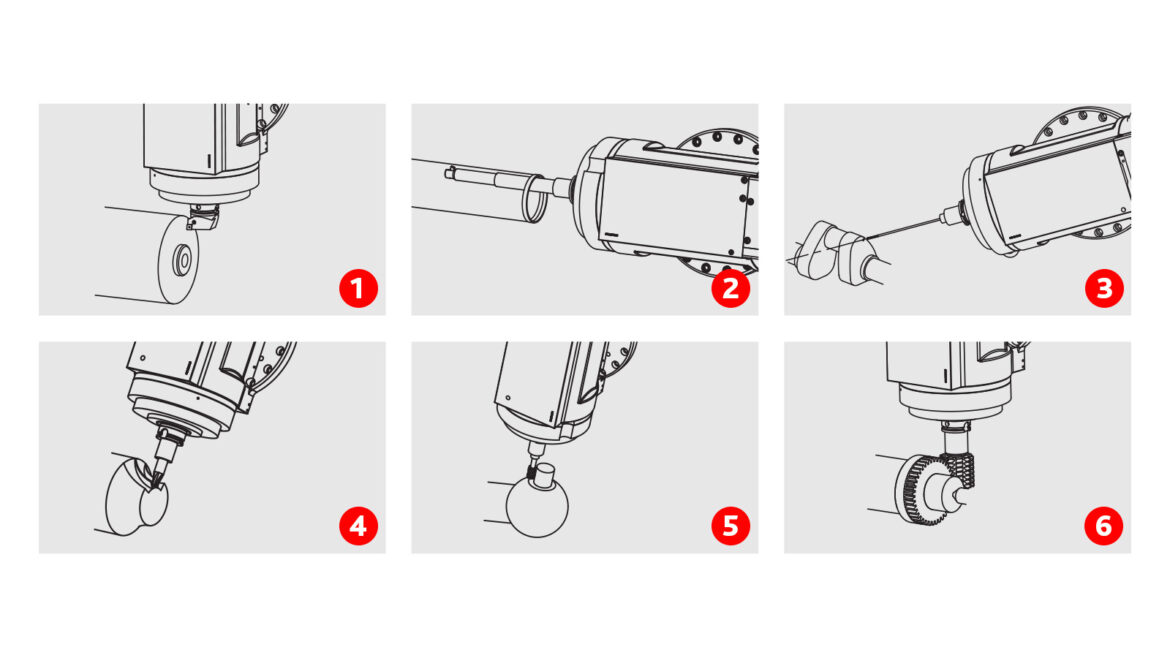

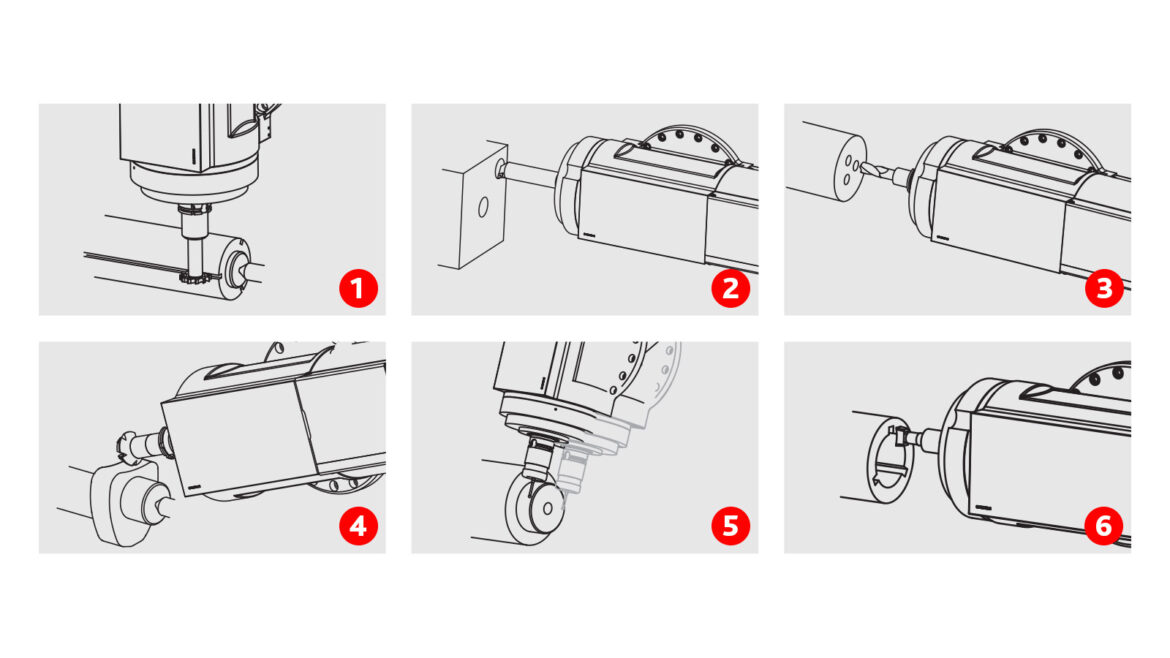

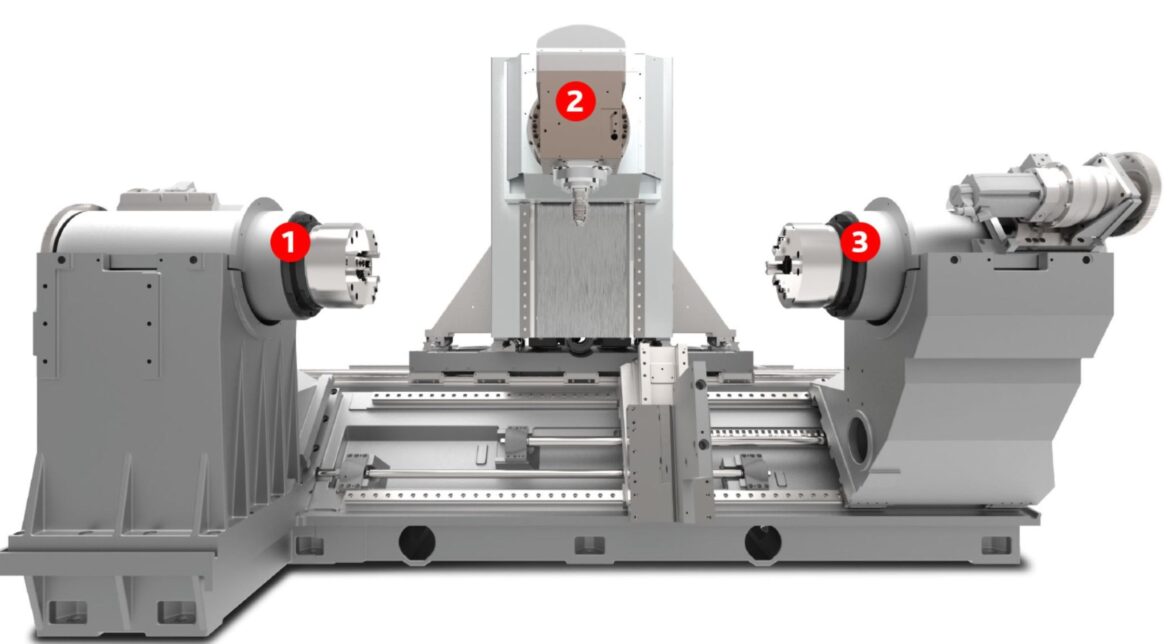

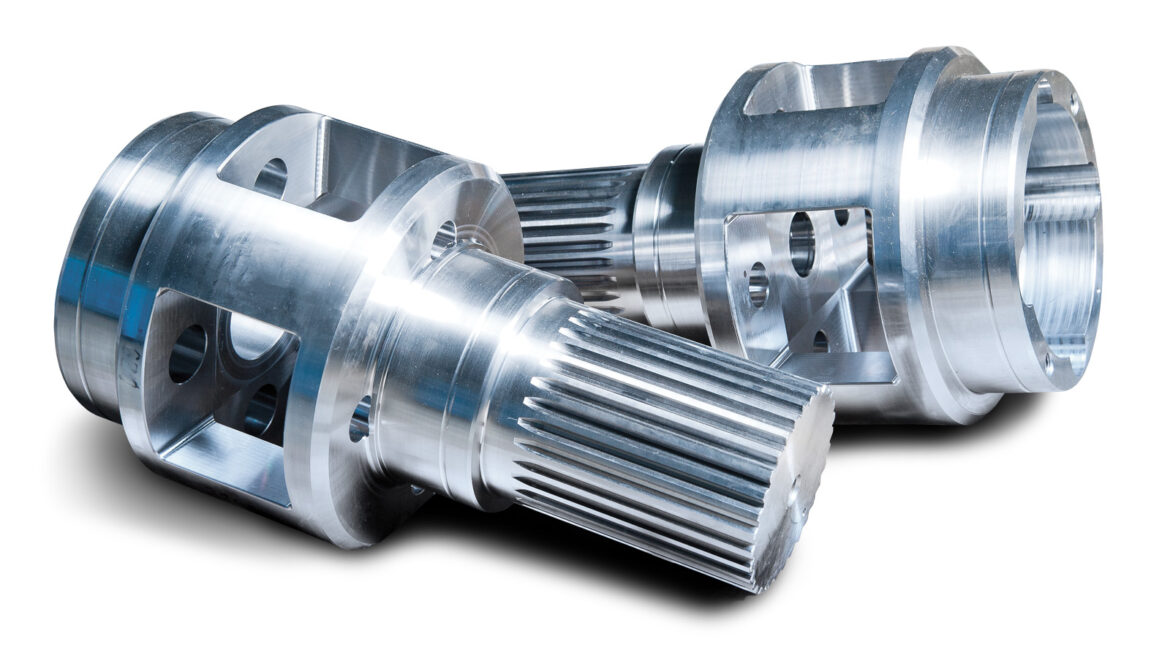

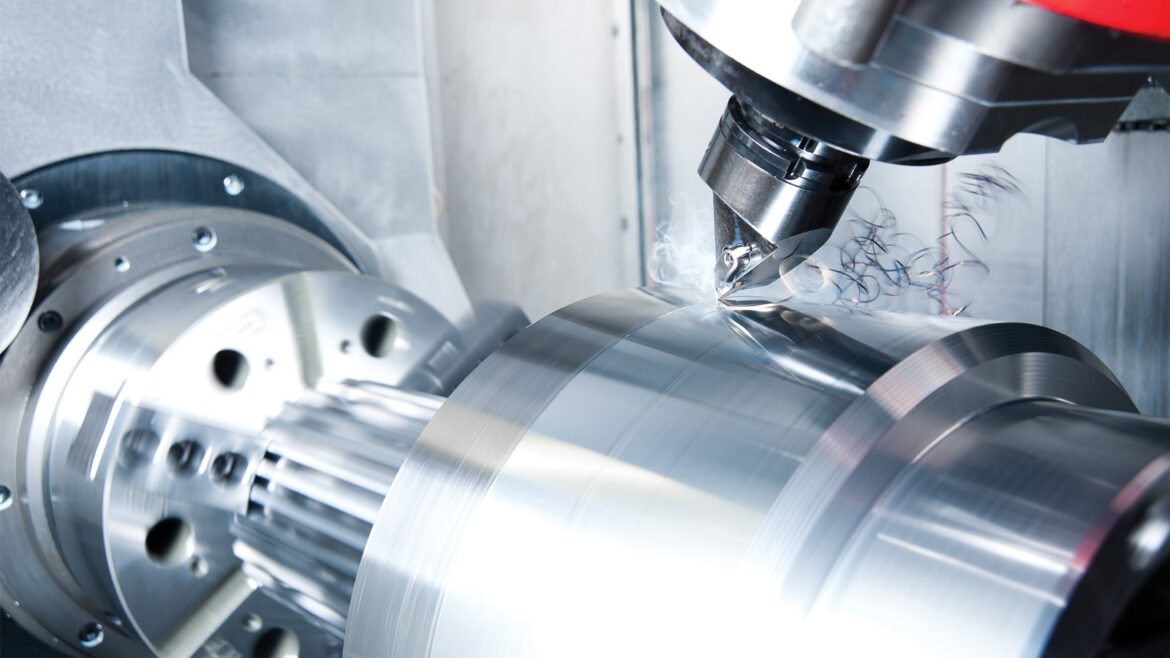

The multitasking turning-milling centers combine the features of turning and milling machines in a single universal machine which has capability to machine complex parts using more technologies (turning, threading, recessing, drilling, boring, milling, cam milling, gear hobbing, and measuring). The machines are equipped with a B-axis as standard which allows an extra-axial drilling and 5-axis milling. The MULTICUT 500i S (with the right spindle) can do a full part machining on both sides.

Machine version

S – version with the subspindle

T – version with the tailstock

| TECHNICAL DATA | MULTICUT 500i [POWER] (T) | MULTICUT 500i [POWER] (S) | |

| Operating range | |||

| Max. swing over bed / lower support | mm | 1300 | 1300 |

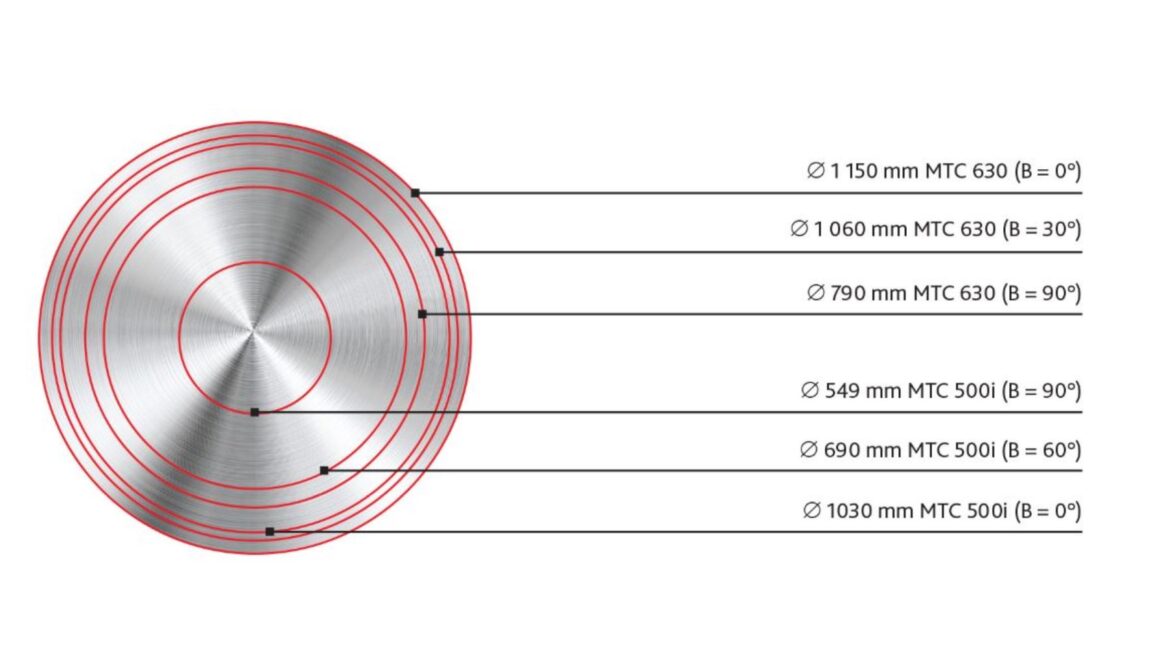

| Max. turning diameter B=0° / 45° / 60° / 90° | mm | 549 / 690 / 880 / 1030 | 549 / 690 / 880 / 1030 |

| Max. distance of faces spindle to tailstock spindle | spindle to spindle | mm | 1972 | 1799 |

| Max. turning lenght | mm | 1734 | 1527 |

| Bar work capacity | mm | 94 [122] | 94 [122] |

| Workpiece weight | |||

| Not supported / supported with center (max. speed) with a chuck | kg | 800 / 2100 [1000 / 2500] | 800 / 2100 [1000 / 2500] |

| Supported with steady rests 1 (max. speed 300 min-1) | kg | 2500 [3000] | 2500 [3000] |

| Linear axes of the tool spindle | |||

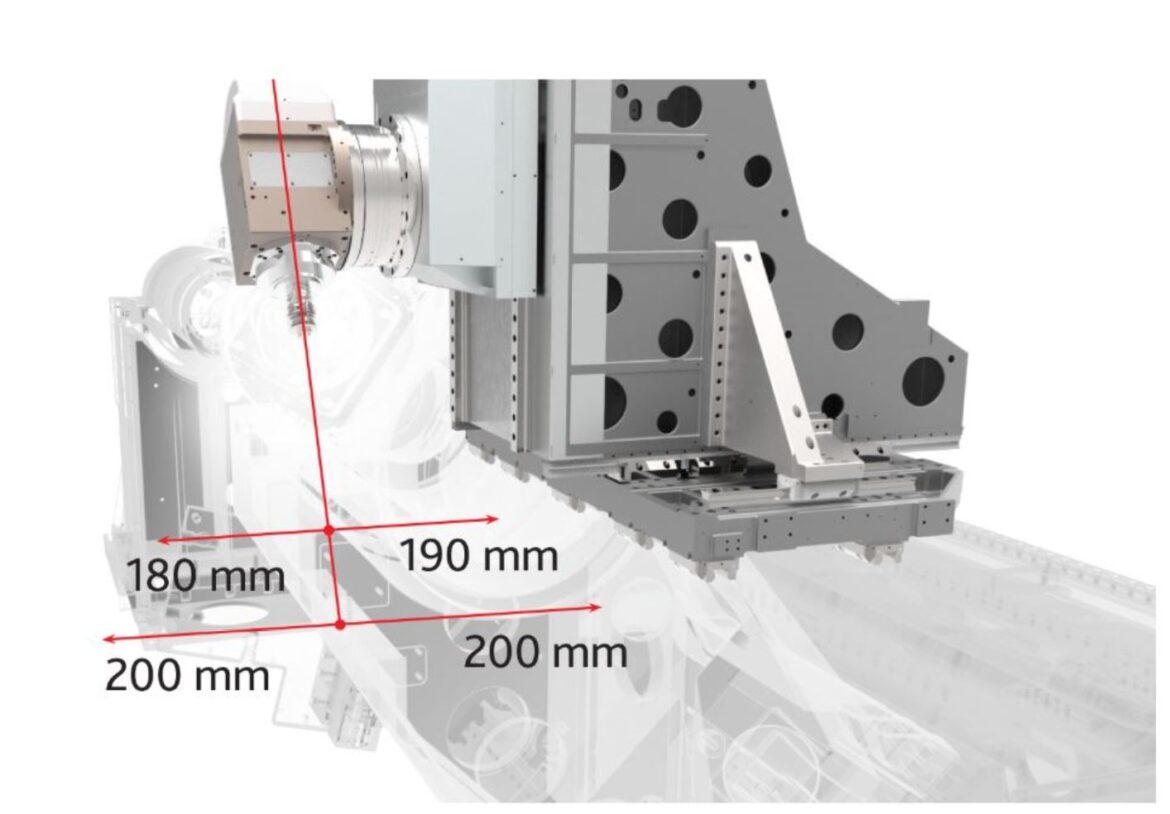

| X / Y <-Y/+Y> / Z axis travel | mm | 640 / 370 <-190+180> / 1600 | 640 / 370 <-190+180> / 1600 |

| Feed force X ; Y ; Z 25% / 40%ED / continuous | kN | 21,5 / 17,5 / 12,5; 19,5 / 16 / 11,5; 32 / 27,5 / 17 | 21,5 / 17,5 / 12,5; 19,5 / 16 / 11,5; 32 / 27,5 / 17 |

| X / Y / Z axis rapid traverse | m.min-1 | 50 / 40 / 50 | 50 / 40 / 50 |

| X / Y / Z axis acceleration | m.s-2 | 05.04.2005 | 05.04.2005 |

| Main spindle | |||

| Max. spindle speed | |||

| Low speed | min-1 | 3500 [866] | 3500 [866] |

| High speed | min-1 | 3500 [2800] | 3500 [2800] |

| Nominal spindle speed | min-1 | 750 [133 / 666] | 750 [133 / 666] |

| Gearbox stages | 1 [2] | 1 [2] | |

| Spindle nose type (DIN 55026) | A8 [A11] | A8 [A11] | |

| Spindle boring | mm | 106 [135] | 106 [135] |

| I.D. of the front bearings | mm | 160 [200] | 160 [200] |

| Torque | |||

| Low speed 25% / 40% / 60%ED / continuous | Nm | 1145 / 1025 / – / 760 [- / 3000 / 2400 / 2000] | 1145 / 1025 / – / 760 [- / 3000 / 2400 / 2000] |

| High speed 25% / 40% / 60%ED / continuous | Nm | 1145 / 1025 / – / 760 [760 / 600 / 480 / 400] | 1145 / 1025 / – / 760 [760 / 600 / 480 / 400] |

| Motor power 25% / 40% / 60%ED / continuous | kW | 74 / 72 / – / 59 [53 / 42 / 33,5 / 28] | 74 / 72 / – / 59 [53 / 42 / 33,5 / 28] |

| Spindle axis height | mm | 1290 | 1290 |

| Subspindle | |||

| Max. spindle speed | |||

| Low speed | min-1 | – | 3500 [866] |

| High speed | min-1 | – | 3500 [2800] |

| Nominal spindle speed | min-1 | – | 750 [133 / 666] |

| Gearbox stages | – | 1 [2] | |

| Spindle nose type (DIN 55026) | – | A8 [A11] | |

| Spindle boring | mm | – | 106 [135] |

| I.D. of front bearings | mm | – | 160 [200] |

| Torque | |||

| Low speed 25% / 40% / 60%ED / continuous | Nm | – | 1145 / 1025 / – / 760 [ – / 3000 / 2400 / 2000] |

| High speed 25% / 40% / 60%ED / continuous | Nm | – | 1145 / 1025 / – / 760 [760 / 600 / 480 / 400] |

| Motor power 25% / 40% / 60%ED / continuous | kW | – | 74 / 72 / – / 59 [53 / 42 / 33,5 / 28] |

| C-axis of workpiece spindles | |||

| Min. programming step | 0,0001° | 0,0001° | |

| Max. speed | min-1 | 43 | 43 |

| Torque 25% ED / continuous | Nm | 2100 / 1400 | 2100 / 1400 |

| Tool spindle | |||

| Max. speed | min-1 | 12 000 | 12 000 |

| Nominal speed | min-1 | 2100 | 2100 |

| Taper | kVa | HSK-63 / Capto 6 [HSK-63] | HSK-63 / Capto 6 [HSK-63] |

| Torque 25% / 40% ED / continuous | Nm | 123 / 100 / 60 | 123 / 100 / 60 |

| Power 25% / 40% ED / continuous | kW | 27 / 22 / 13 | 27 / 22 / 13 |

| Number of tool indexing positions | 360 x 1° | 360 x 1° | |

| Spindle length | mm | 563 | 563 |

| B axis of tool spindle | |||

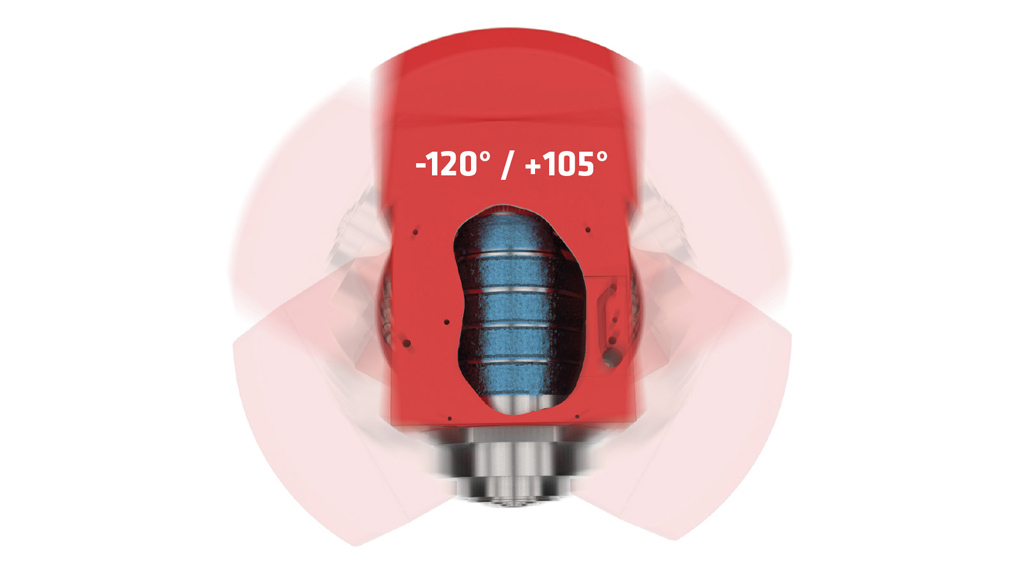

| Range | ° | -120° / +105° | -120° / +105° |

| Min. programming step | 0,0001° | 0,0001° | |

| Max. speed | min-1 | 50 | 50 |

| Time of indexing by 90° | s | 0,8 | 0,8 |

| Torque 40% ED / continuous | Nm | 950 / 550 | 950 / 550 |

| Hydraulic brake / locking | Nm | 4000 | 4000 |

| Tool magazine | |||

| Tool storage capacity | 81 | 81 | |

| Max. tool length | mm | 350 | 350 |

| Max. tool diameter with / without adjacent HSK-63, Capto C6 | mm | 150 / 90 | 150 / 90 |

| Max. tool weight | kg | 8 | 8 |

| Tool to tool / chip to chip change time | s | märts.15 | märts.15 |

| Tailstock | |||

| Tailstock spindle diameter / Tailstock spindle travel | mm | 190 / 180 | – |

| Taper hole of tailstock spindle Morse | Mo6 | – | |

| Force range | kN | 3,2 – 28,6 | – |

| Tank capacity | |||

| Tank capacity / coolant volume | l | 500 / 620 | 500 / 620 |

| Pump motor power / continuous | kW | ||

| Machine dimensions | |||

| Machine length without / with chip conveyor / for transport | mm | 4800 / 6500 / 5372 [6385 / 7425 / 6692] | 4800 / 6500 / 5372 [6385 / 7425 / 6692] |

| Machine width / for transport | mm | 3950 / 3670 | 3950 / 3670 |

| Machine height / for transport | mm | 3760 / 3660 | 3760 / 3660 |

| Machine weight | kg | 22 800 [23 750] | 23 050 [24 000] |

| Machine connection | |||

| Eletrical power supply / continuous | kVA | 110 [90] | 110 [90] |

| Compressed air supply / pressure / flow | MPa/L.min-1 | 0,6 / 600 | 0,6 / 600 |

| Control system | |||

| Type | Siemens Sinumerik 840D SL | Siemens Sinumerik 840D SL | |

| Number of continuously controlled axes for machining | 5 | 5 | |