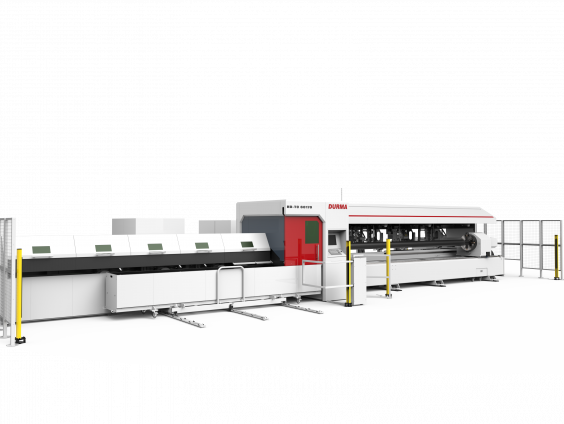

HD-TC Durma tube-cutting machine

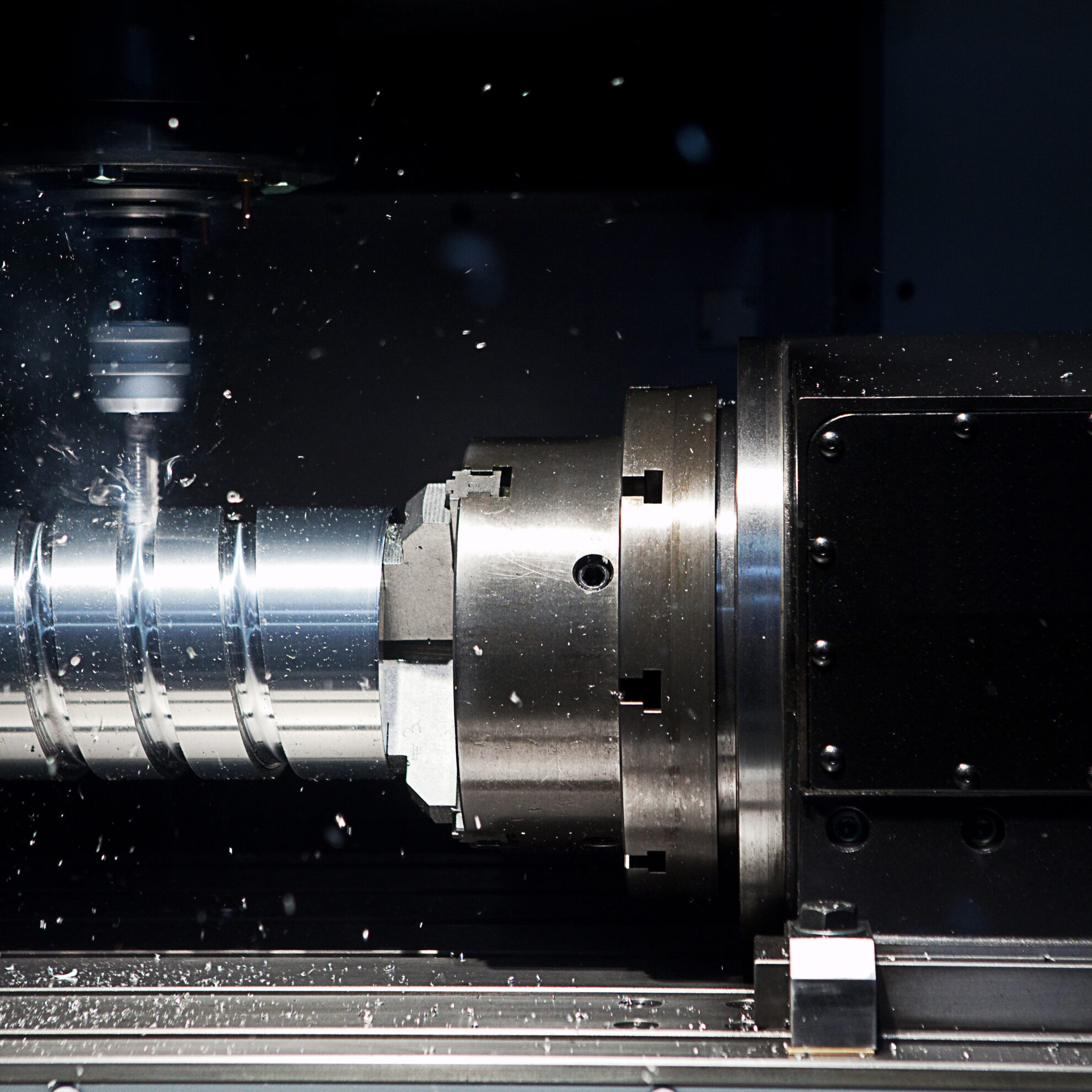

The pipe laser cutting machine has been specifically developed for companies that value high quality cutting of pipes (up to 220 mm diameter) and profiles. Thanks to its cutting power of up to 3 kW, the laser can cut tubes and profiles from 0.8 mm to 10 mm thick. Fully automatic loading and unloading requires less effort and saves operator time. The moving axes are driven by maintenance-free, dynamic and high-performance AC servo motors. Dust generated by laser cutting is sucked into a dust collection filter by a suction system.

An automatic tube and profile infeed system is designed to reduce material preparation time, and an automatic tube and profile outfeed system collects the cut material without stopping the machine. Thanks to the compact design of the tube laser, all tube and profile insertion/cutting/extracting operations require less space and less processing. The HD-TC pipe laser cutter stands out for its speed, high quality components, efficiency and industrial design.

The HD-TC tube cutting machine can be used in a wide range of industries such as automotive, furniture, shelving and machinery, construction, agricultural machinery and steel structures. The use of tubes and profiles is widespread in many sectors. Processes such as cutting geometric shapes are easy to perform. The use of laser technology to cut tubes and profiles provides the opportunity to create aesthetic and flexible designs.

What are the advantages of the Durma HD-TC tube cutting laser?

- User-friendly

The Durma HD-TC pipe laser has been specifically developed with user-friendliness in mind. Its automated workflow saves you time. Its ergonomic design makes it easy to use. - Energy efficient

The Durma HD-TC tube laser cutter is designed with energy efficiency in mind. Its advanced technology and design are optimised to save space and energy. The machine is fast, ergonomic and easy to use. The advanced technology keeps the machine’s operating costs low. - Reliable

Durma technology is engineered for precise results. Durma Tube Laser HD-TC is durable and reliable and will serve you for many years. Precise technology ensures reliable results.

Two different units are available:

Durma HD-TC 60170 (max diameter 170mm, square max 120mm, rectangle 150*100mm).

Durma HD-TC 60220 (max diameter 220mm, square 160mm, rectangle 200*100mm).

Low Operating Costs

Low energy consumption

Low cost per component

Optimised focal distance for all thickness values

Maintenance free operation

Compact design, fast installation

Rigid body structure, high durability

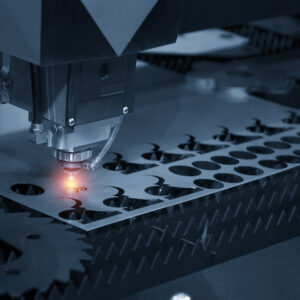

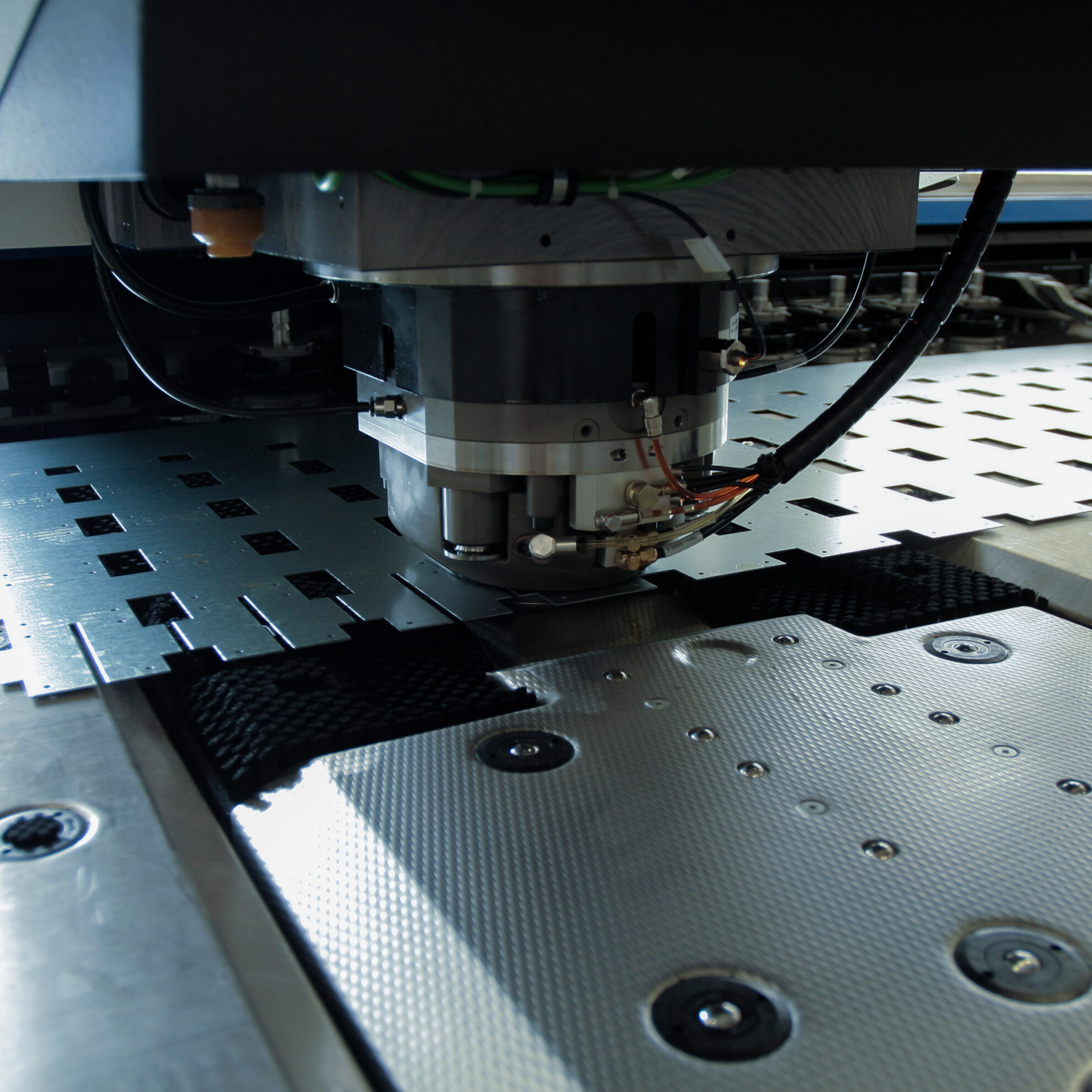

Laser cutting head

ProCutter offers a complete solution for laser-based fusion cutting of thin and medium thickness materials. With flame cutting, thicker materials can be processed while maintaining high quality standards.

Automatic loading system

Profiles are transferred one after the other from the stack to the transfer chain, the system moves the profile upwards, grippers grip the profile and move it to the cartridge axis, the cartridge holds the profile.

Measuring the length of the profile

A servomotor is used to measure the length of the profile and transmit the data to the system.

Pipe handling system

The pipe transfer system ensures that the pipes are guided in the correct position on the cutting line.

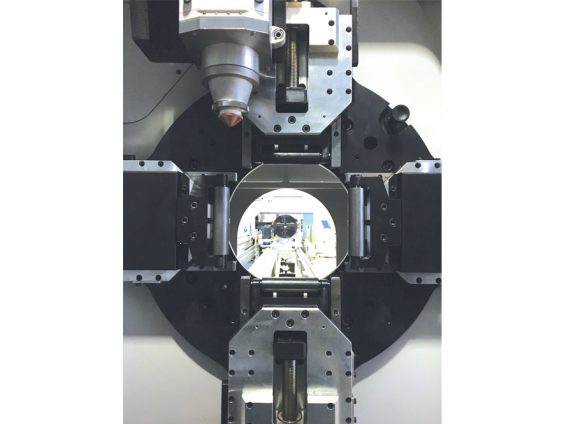

Hydraulic profile holder

Allows the holding of a wide range of profiles by means of 4 clamps operating independently on the 2+2 principle. The hydraulic pressure is automatically adjustable according to the thickness of the profile material.

Chain-retaining system

The chain-retaining system allows the loading of stainless steel, aluminium, brass, etc. pipes without scratching them.

Z-axis

Enables a faster cutting process thanks to its high dynamic performance. Auto-focus laser head reduces the time needed for cutting in the preliminary preparation phase.

Automatic loading gripping system

Tubes arriving from the loading unit are automatically moved to the cutting area and centred.

Profile support system

4 support arms with servo motors keep the loading at the same level as the hydraulic cartridge. When the hydraulic cartridge moves the profile along the X1 axis, the support arms close one after the other to open the front of the hydraulic cartridge.

Splash protection system

The splash guard system shall be used to prevent the slag formed on the cutting edge from adhering to the mating surface of the profile. Scratches adhering to the inner surface of the profile reduce the quality of the cut and necessitate cleaning of the inner surface of the parts. A splash protection system prevents all these problems.

Automatic dispensing system

The height of the support mechanism of the discharge unit is controlled by a servomotor, the profile is supported during cutting.

Available in 4 m and 6 m versions.

Front and rear variants available.

The discharge table can remove the cut tubes from the cabin by its own in-out movement.

Seam detection sensor

The seam detection sensor installed on HDTC machines detects the surface of the pipe with a seam.

when loading into the machine and allows the operator to rotate the cut openings to any angle.

Centering system with laser sensors

The recently added laser-sensing centering capability on HDTC machines allows the profile size and uneven structure to be checked during or before cutting using sensors to ensure that the internal contours to be cut are properly centered.

| Tube-Cutting Technical Specifications | |

| Max Diameter (mm) | Ø170 |

| Max Square Tube Dimension(mm) | 120×120 |

| Max Rectangular Tube Dimension (mm) | 150×100 |

| Min. Diameter (mm) | Ø20 (Ø12 Option) |

| Max. Tube Lenght (mm) | 6500 |

| Min. Tube Lenght (for automatic loading) | 3000 |

| Max. Tube Weight (kg/m) | 37,5 |

| Max. Material Thickness (mm) (for 2 kW ) | 8 |

| Min. Material Thickness(mm) | 0,8 |

| Automatic Loading | Yes |

| Automatic Unloading | Yes |

| Cutting Head | 2D |

| Amount of Chuck | 1 |

| Centering Chuck | Yes |

| Last Cut Tube Lenght (mm) | 185 |

| Velocity of Driver Chuck (m/dk.) | 90 |

| Acceleration of Driver Chuck (m/s²) | 10 |

| Accuracy (mm) | ±0,20 |

| Positioning Accuracy (mm) | ±0,05 |

| Tube Types | Pipe, Square, Rectangular, Eliptic H, C, U, L |