| Max. sheet metal cutting thickness depending on laser power* | ||||||

| Material | 1 kW | 2 kW | 3 kW | 4 kW | 6 kW | 8 kW |

| Untensed steel | 8 | 12 (16) | 16 (20) | 20 (22) | 25 | 25 (30) |

| Stainless steel | 4 | 6 (8) | 8 (10) | 10 (12) | 15 (20) | 20 (25) |

| Aluminium | 4 | 6 (8) | 8 (10) | 12 (15) | 20 (25) | 25 (30) |

| Copper | 2 | 3 | 5 | 6 | 10 | 12 |

| Brass | 4 | 6 | 8 | 10 | 12 | 15 |

* Cutting values when cutting material is with a clean surface.

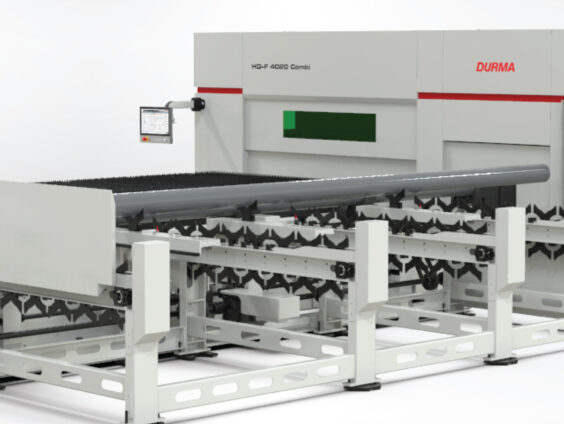

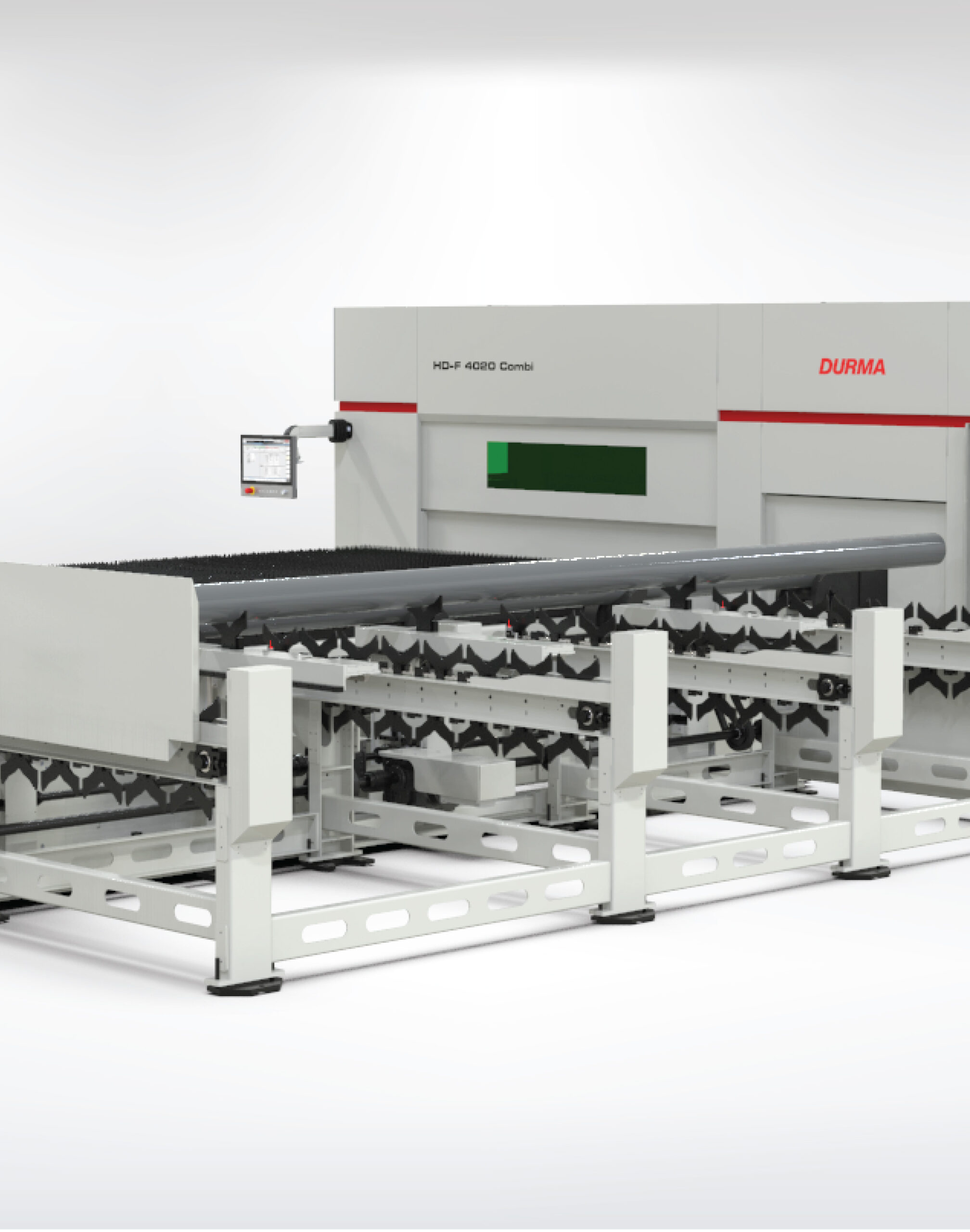

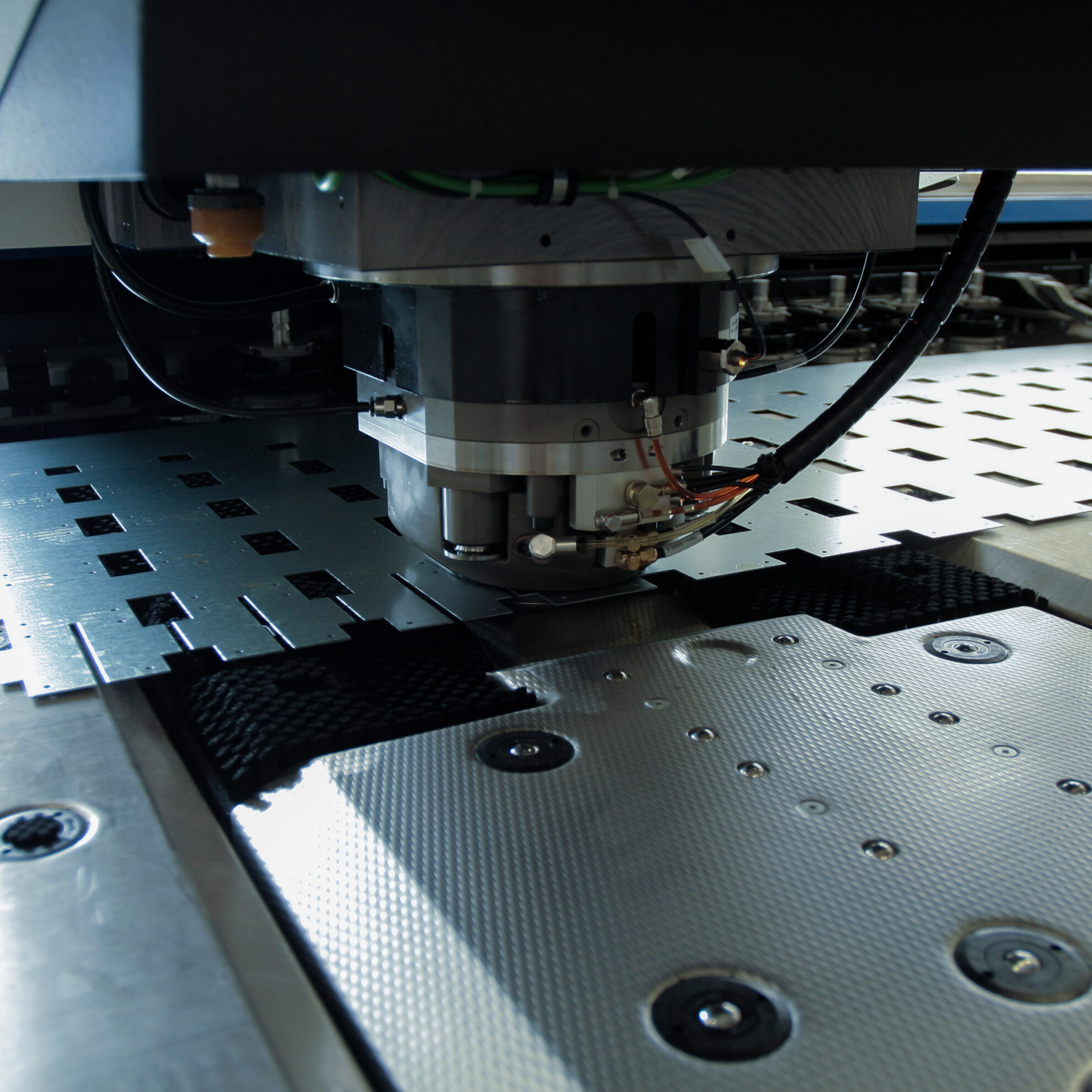

| Pipe and profile cutting specifications (HD-F 3015 & HD-F 4020 & HD-F 6020) | ||

| Max. pipe diameter | 170 | mm |

| Max. square profile diameter | 120×120 | mm |

| Max. rectangular profile diameter | 150×100 | mm |

| Min. pipe diameter | 20 (12 Ops.) | mm |

| Max. length of tube | 6500 | mm |

| Max. length of the tube for automatic loading | 4500 | mm |

| Max. length of the tube for manual loading | 6000 | mm |

| Max. material weight | 37,5 | kg/m |

| Max. total material weight | 210 | kg |

| Cutting accuracy*** | ±0.2 | mm |

* 6500 mm for HD-F 6020

** 6500 mm for HD-F 6020

*** The maximum cutting accuracy depends on the type of profile to be cut and the production method.

| Max. tube cutting thickness depending on laser power* | ||||

| Material | 1 kW | 2 kW | 3 kW | 4 kW |

| Untensed steel | 4 | 8 | 10 | 10 |

| Stainless steel | 2 | 4 | 6 | 6 |

| Aluminium | 3 | 6 | 6 | 6 |

| Copper | 1 | 2 | 3 | 3 |

| Brass | 2 | 4 | 6 | 6 |

* Cutting values when cutting material is with a clean surface.

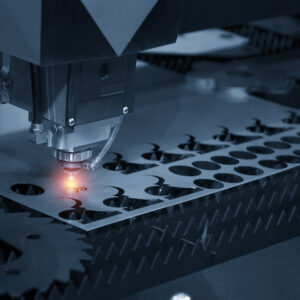

The ProCutter offers a complete solution for laser-based fusion cutting of thin and medium thickness materials at wavelengths of around 1 μm. With flame cutting, thicker materials can be processed while maintaining high-quality standards. The cutting head will increase production, especially for platform and tube cutting machines, where innovative technologies are combined with the knowledge gained. This results in the best possible performance, flexibility and reliability. The combination of proven technology and optimized design allows laser processing with power up to 10 kW. The robust and dust-resistant housing ensures a long lifetime and allows external linear accelerations of up to 4.5 g, creating the prerequisites for efficient cutting. High-quality optics and adherence to the highest quality standards in manufacturing and assembly ensure optimum control and shape of the laser beam, even at high power.

* 8 tubes can be added to the loader at a time.

* Different types of pipes can be loaded at the same time. (in the order of the program list)

* Tubes from Ø12 to Ø170 can be loaded.

* Open pipes (L, U) can be loaded.

* After loading on the cutting line, the system automatically measures the lengths of the pipes.

* If the wrong pipe is loaded on the machine (different from the program sequence), the measuring system automatically detects it, gives an alarm and stops the machine.