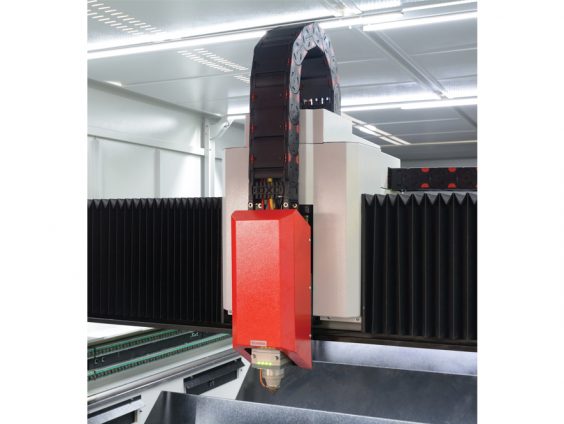

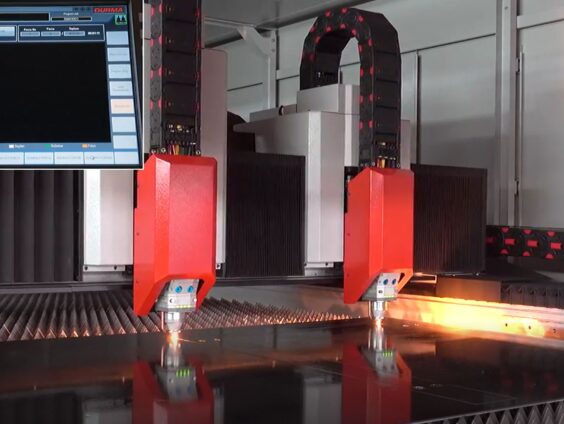

Laser cutting machine DURMA HD-F

The Durma HD-F laser cutting machine stands out for its high-speed cutting technology. These machines are energy efficient and user-friendly thanks to the excellent fiber laser cutting technology. The Durma laser cutter ensures higher quality, performance and efficiency for your production. Servo motor driven gear motors enable the bench to achieve remarkable speeds. The HD-F laser is one of the best in its field thanks to its rigid modular design, excellent filtration system, compact design and efficient, user-friendly construction.

What are the advantages of the Durma HD-F laser cutting machine?

- Efficient

The Durma HD-F laser cutter has a reinforced, low-bottomed, modern frame and a special alloy bridge design. The machine is designed to achieve high cutting speeds. Durma uses slackless reducers in its machines. This system ensures laser positioning accuracy and repeatability of ±0.05 mm. In this way, the machine achieves a high degree of accuracy and stability.

2. Flexible

The HD-F is a flexible machine, ready to meet your production needs. The machine has a selectable configuration optimised for a wide range of applications. Its versions for straight and bevel cutting are tailored just for you. Durma is able to produce flexible, customer-oriented solutions equipped with in-house developed NC/PLC/HMI software.

3. User-friendly

HD-F series laser cutting machines are equipped with Durma’s flexible and operator-friendly HMI interface software. In addition, the Durma Cloud program ensures instant machine monitoring, efficiency calculations and preventive maintenance in the event of breakdowns. The machine is equipped for optimal control. It has been developed with user-friendliness in mind and saves you time, energy and manpower.

The HD-FL linear motor solution is also available.

HD-F series fiber lasers stand out for their cutting speed and energy efficiency, especially compared to CO lasers.

- Specifically designed that care about floor space

- User Friendly

- Low Operating Costs

- Fast Movable Upper Cover

- Easy Access To Cutting Area

- Compact Bridge Design

- Easy Transport

| HD-F / HD-FL Fiber Laser | ||||||

| 3015 | 4020 | 6020 | 8020 | 12020 | ||

| X Axis | 3060 | 4100 | 6150 | 8200 | 12200 | mm |

| Y Axis | 1530 | 2100 | 2100 | 2100 | 2100 | mm |

| Z Axis | 160 | 185 | 185 | 185 | 185 | mm |

| Max. Sheet Size | 3048 x 1524 | 4064 x 2032 | 6096 x 2032 | 8128 x 2032 | 12192 x 2032 | mm |

| ax. Sheet Weight | 200 | 200 | 200 | 200 | 200 | Kg/m² |

| Rack&Pinion HD-F Lineer System HD-FL | ||||||

| 100 160 | m/min. | |||||

| Y Axis | 120 160 | m/min. | ||||

| Synchronous | 170 226 | m/min. | ||||

| Acceleration | 28 32 | m/s² | ||||

| Positional Accuracy | ±0,05 ±0,03 | mm | ||||

| Repeatability | ±0,05 ±0,03 | mm | ||||

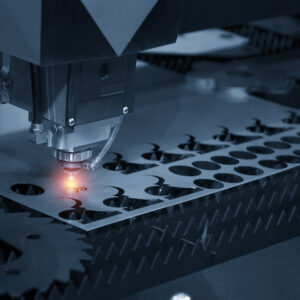

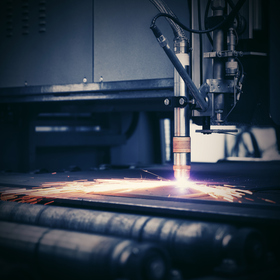

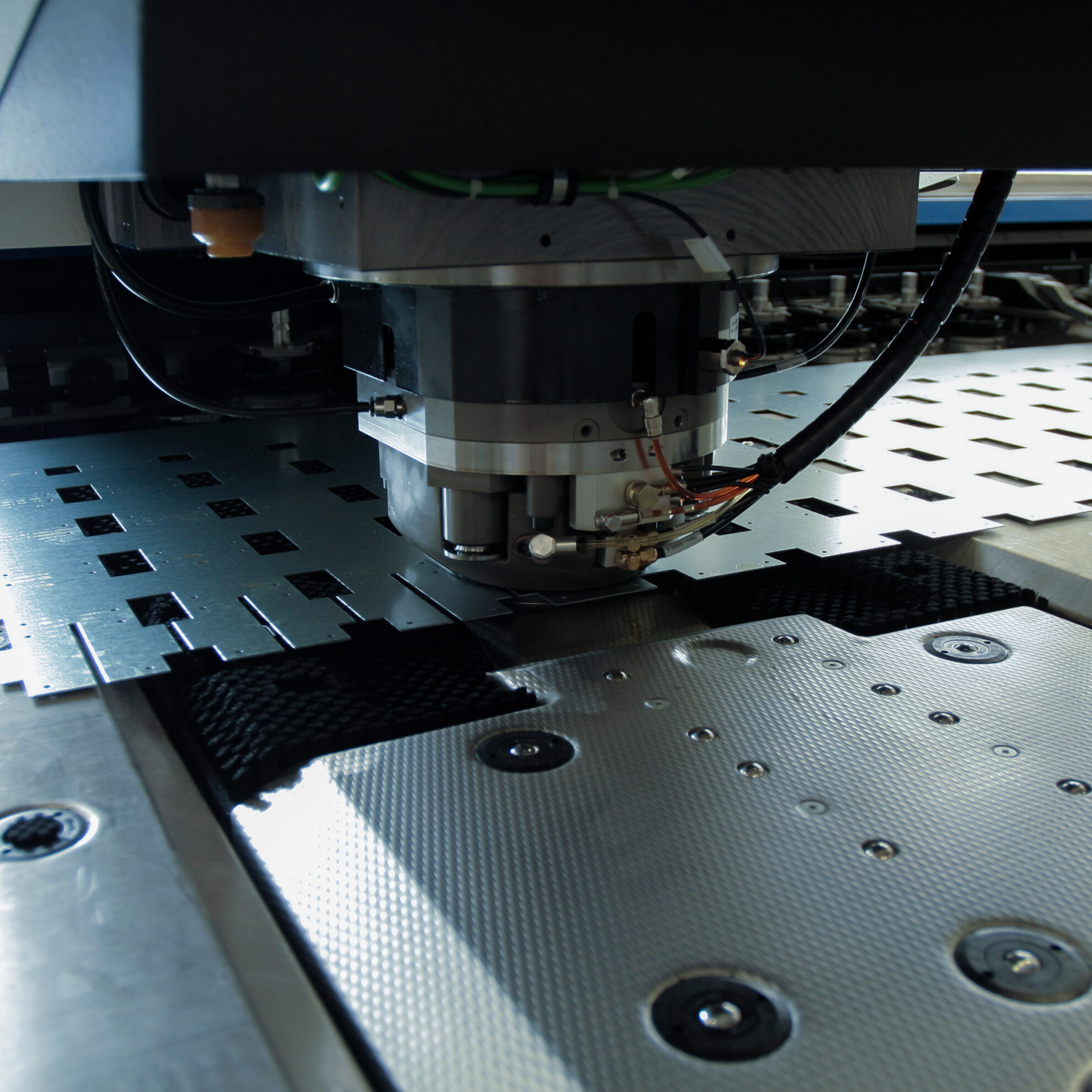

The ProCutter offers a complete solution for laser-based fusion cutting of thin and medium thickness materials at wavelengths of around 1 μm. With flame cutting, thicker materials can be processed while maintaining high quality standards. The cutting head will increase production, especially in platform and tube cutting machines, where innovative technologies are combined with the knowledge gained. This results in the best possible performance, flexibility and reliability. The combination of proven technology and optimized design allows laser processing with power up to 10 kW. The robust and dust-resistant housing ensures a long lifetime and allows external linear accelerations of up to 4.5 g, creating the prerequisites for efficient cutting. High-quality optics and adherence to the highest quality standards in manufacturing and assembly ensure optimum control and shape of the laser beam, even at high power.

The ProCutter offers a complete solution for laser-based fusion cutting of thin and medium thickness materials at wavelengths of around 1 μm. With flame cutting, thicker materials can be processed while maintaining high quality standards. The cutting head will increase production, especially in platform and tube cutting machines, where innovative technologies are combined with the knowledge gained. This results in the best possible performance, flexibility and reliability. The combination of proven technology and optimised design allows laser processing with power up to 10 kW. The robust and dust-resistant housing ensures a long lifetime and allows external linear accelerations of up to 4.5 g, creating the prerequisites for efficient cutting. High-quality optics and adherence to the highest quality standards in manufacturing and assembly ensure optimum control and shape of the laser beam, even at high power.