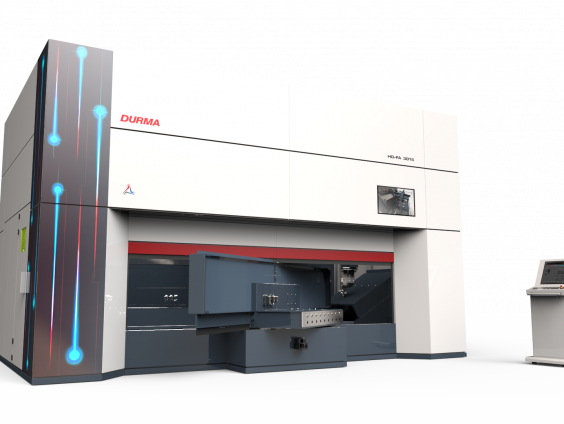

5-axis laser cutting machine HD-FA

The HD-FA is suitable for use in the automotive industry and for all other demanding complex three-dimensional parts. The machine’s sturdy frame and rotary table ensure ideal cutting performance and high accuracy. The result is a high quality 3D cut. The cutting system of the HD-FA 5-axis laser cutting machine features an easy-to-operate jig. This saves both time and energy. In addition, the HD-FA has an impressively fast, reliable and efficient design.

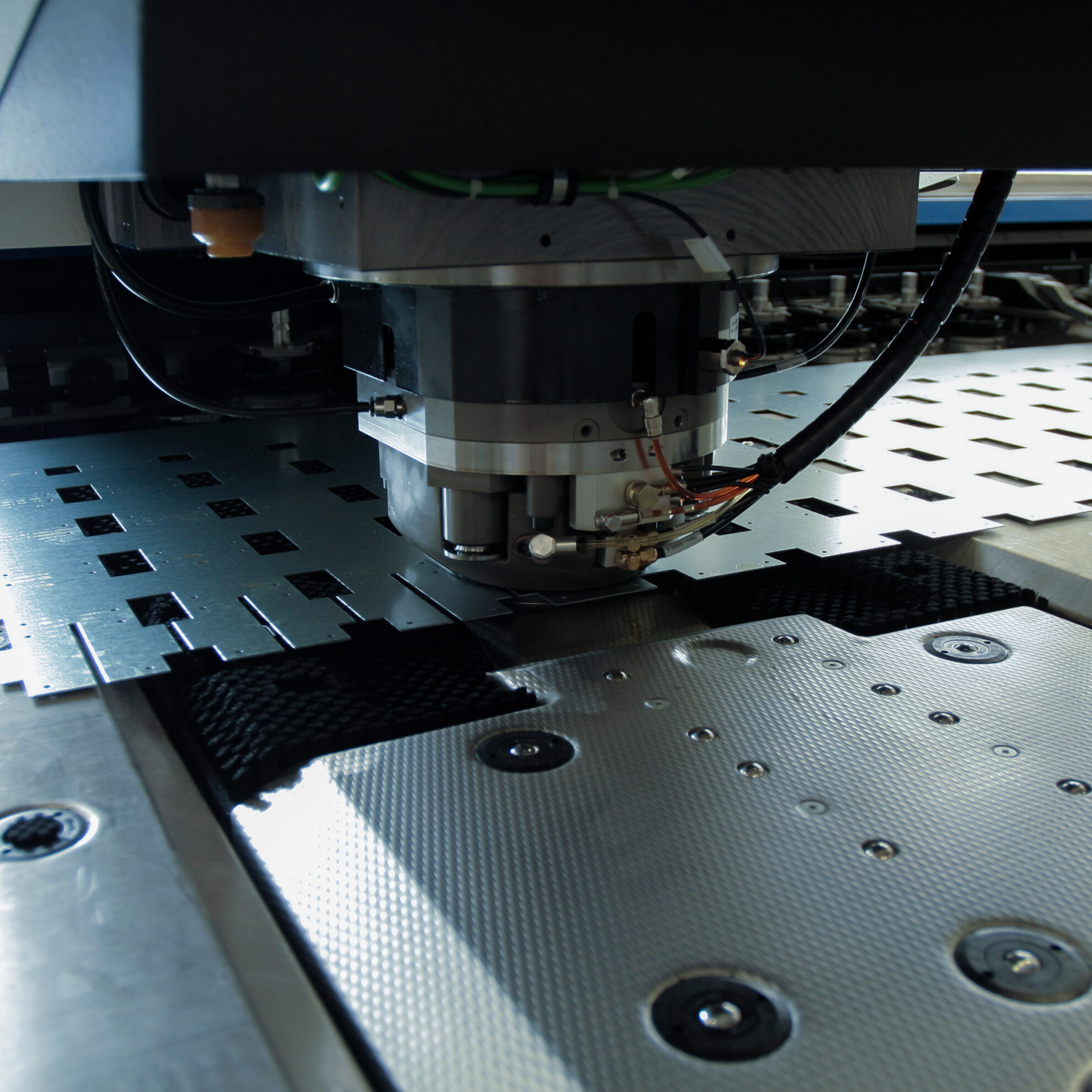

HD-FA laser cutting machine technology

- Modern and compact design

When developing the HD-FA, compactness was an important consideration. With its modern design, it requires less space as well as less energy compared to other similar machines. - Easy to use

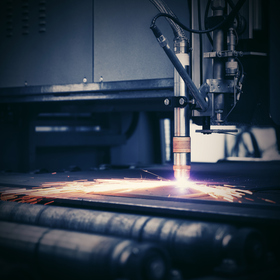

The Durma 5-axis laser cutter is user-friendly. Its automated workflow saves your time. If you are looking for a machine that is efficient and easy to operate, this is the right choice for you. The HD-FAl is an easy-to-use jig that allows you to quickly and easily position the third and second piece to be cut, ensuring faster production and increased productivity. - High-quality 3D cutting

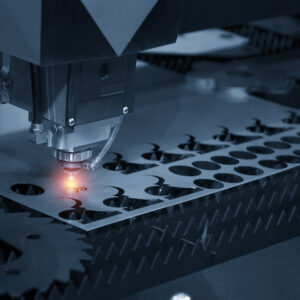

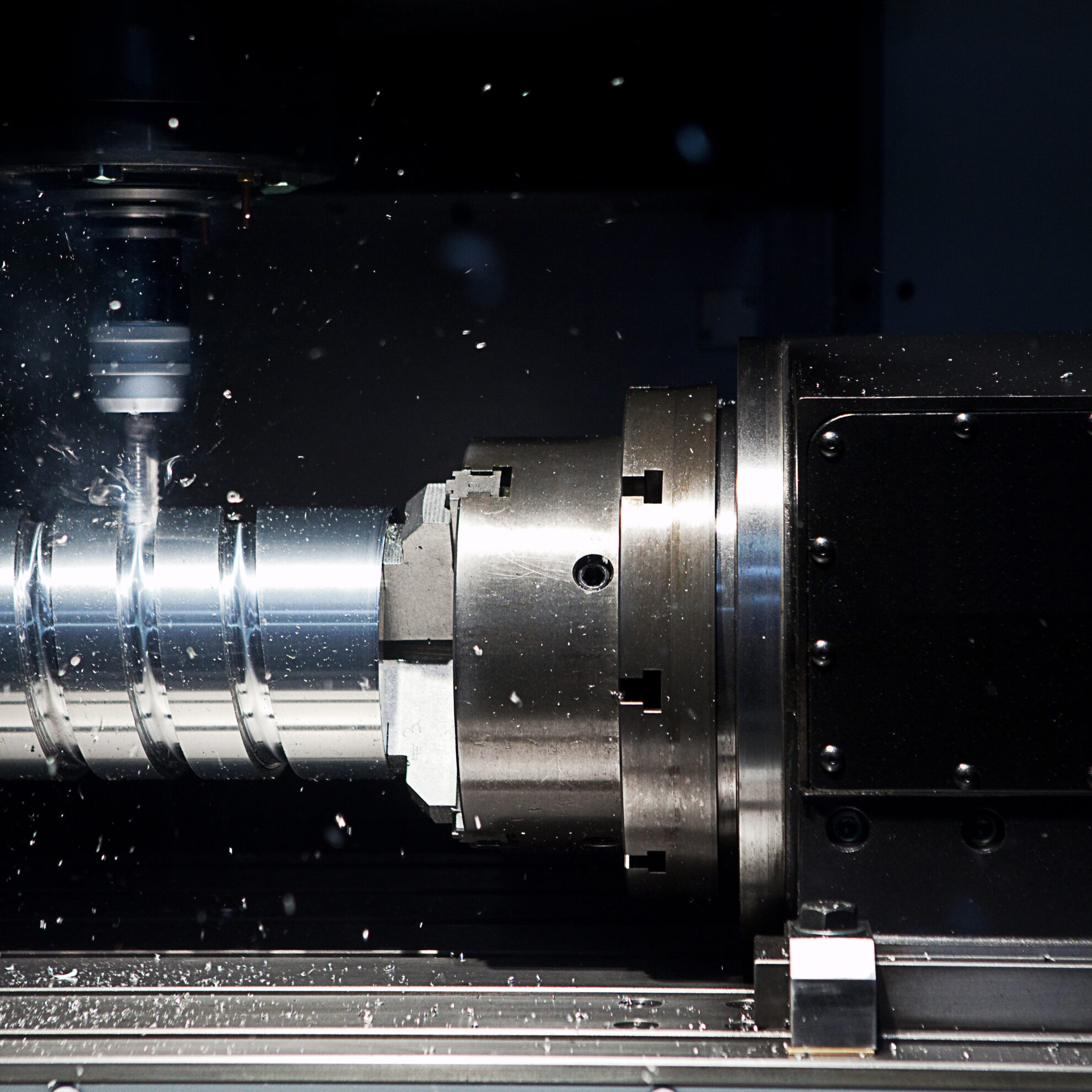

The HD-FA is assembled from high-quality parts to ensure high-quality 3D cutting. This ensures high performance and stable, reliable cuts. The highest quality materials have been used to manufacture the laser cutting machine. - Low power consumption

Energy efficiency has been taken into account when designing the laser cutting bench. Durma’s advanced technology has been developed specifically to ensure low running costs. The machine saves your energy costs as well as time and labor.

- Modern and Compact Design

- Easy to use Fixture Globally

- High Performance Components

- High Quality 3D Cutting

- Low Energy Consumption

- Faster, Reliable, Efficient

| HD-FA 5 AXIS TECHNICAL SPECIFICATIONS | |||

| X axis stroke | 3000 mm | ||

| Y axis stroke | 1500 mm | ||

| Z axis stroke | 650 mm | ||

| B axis | ±135° | ||

| C axis | ±360°xn | ||

| Max. Synchronous speed | 173 m/dk. | ||

| Max. Acceleration | 1,73 G | ||

| Positional Accuracy | ±0.08 mm | ||

| Repeatability | ±0.08 mm | ||

| MACHINE SIZES | |||

| Machine size | 6168 mm x 3936 mm h= 3700 mm | ||

| Working Area | 9.000 mm x 10.000 mm (Secure area) | ||

| Rotary Table’s Door Length | 4.000 mm | ||

| Machine Weight | 16.000 kg | ||

| CUTTING THICKNESS | |||

| Power | 2kW | 3kW | 4kW |

| Mild Steel (mm) | 12 | 16 | 20 |

| Stainless Steel (mm) | 6 | 8 | 10 |

| Aluminum (AIMg3) (mm) | 6 | 8 | 12 |

| Brass (mm) | 6 | 8 | 10 |

| Copper (mm) | 3 | 5 | 6 |

| CUTTING HEAD | |||

| Type | 3D | ||

| Focus | Automatic | ||

| CONTROL UNIT | |||

| CNC | SIEMENS SINUMERIK 840D SL | ||

| Screen | 15″ Touch panel | ||

| FILTER | |||

| Capacity | 2.500 m³/h – 4 kW | ||

| CHILLER | |||

| IPG LG 71 | |||

| IPG LG 170 | |||

| IPG LG 171 | |||