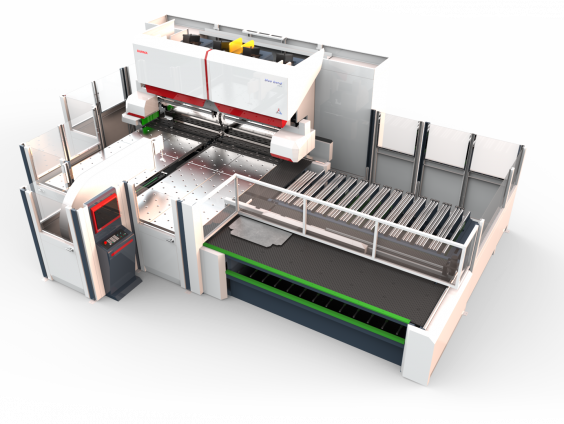

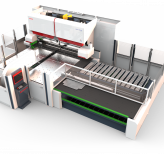

Durma Panel Bender

Our latest member of Durma inventory, Durma Panel bender is produced to increase effiency on piece production with it advanced technology.

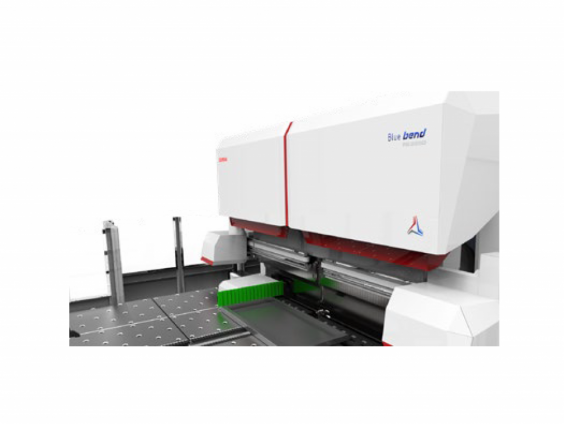

Maximum speed and safety, fully automatic tool changing capacity and minimized adjustment timing, it provides excellent outcome.

Durma panel bender, with robust frame, excellent precision and ergonomic design it provides high productivity on your production and it will take place in establishment with its variety bending possibilities.

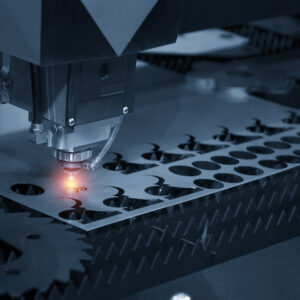

As automation with Laser and Punch machines combinations, Durma Panel bender will obtain superior time benefit on processing times.

Our developed smart consumption, operator free standard production and stabil thermal condition studies Durma panel bender, will provide opportunities energy savings as energy costs increasing developing World.

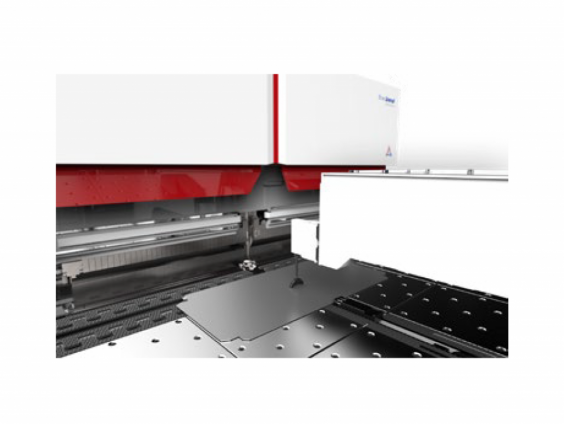

Durma Panel bender offers both simple and full automatic bending’s between thickness of 0,5 – 4 mm

User Friendly Durma Panel Bender, with its easy to use interface and programming software it will be your partner for all sorts of solutions.

Perfectly equipped for bending Energy efficient solutions.

Precise bend with, Maximum speed, safety full automatic tool changing and minimum set-up time. With its easy to use control units, rigid body frame, perfect design, high efficiency, multiple tool usage solutions.

– Compact Solution

– Ergonomic and Safe Working Area

– Energy safetynwith clever consumption system

– Regular Production Independent From the Operator

– Stabil Process «No Influence» From the Machine Thermal Conditions

Universal Bending / Holding Tools

CAD-CAM software & Activator(Dongle)

Control Unit, Siemens Sinumerik 840 D SL Windows 7 operating system

Remote diagnostic function

Network, Ethernet communication

Programming on the control panel

ATS – Automatic Tool Setup

Standart Clamp for manipulator

Crowning Bending Device

Crowning Holder Device

Brush table

USB Driver

Air Condition for Electrical Cabinet

400 V Voltage

Barriers for CE

World standard electric equipment

| Panel Bender Technical Details | |||

| Technical Specifications | |||

| PB2 | PB4 | ||

| Max. Bending Lenght | mm | 2250 | 2800 |

| Min. Bending Lengh | mm | 350 | 350 |

| Max. Sheet Enterance Lenght | mm | 2600 | 3050 |

| Max. Sheet Enterance Width | mm | 1524 | 1524 |

| Min. Bending Width | mm | 150 | 150 |

| Max. Bending Height | mm | 254 | 254 |

| Max. Bending Depth | mm | 50 | 50 |

| Max. Diagonal | mm | 3300 | 3300 |

| Bending Force | KN | 320 | 500 |

| Holding Force | KN | 520 | 1000 |

| Max. Thickness of Sheet | |||

| for Fe 410 N/mm2 Material | mm | 2,6 | 3,2 |

| for Inox 600 N/mm2 Material | mm | 1,8 | 2,2 |

| for Aluminium 260 N/mm2 Material | mm | 3,5 | 4 |

| Min. Thickness of Sheet | mm | 0,5 | 0,5 |

| Max. One Step Bending Angle | * | ±135° | ±135° |

| Advanced Specification | |||

| Negative Last Bend | Standard | ||

| Automatic Tool Setup | ATS (Standard) | ||

| Inverse Bending Ranking | Standard | ||

| Auxiliary Holder Tools | AHD (Option) | ||

| Auxiliary Lower Bending Tools | AB (Option) | ||

| Auxiliary Upper Bending Tools | AB (Option) | ||

ABD – Auxiliary Bending Devi ce

ABT – Auxiliary Bending Tools and Brackets

AHD – Auxiliary Holder Device

AHT – Auxiliary Holdind Tools

OC – Over Clamp

NPF – Narrow Part Feeder

ENG – Engraver

Working Table (Brush & balls)

Loading / Unlading System

Transformator

UPS for machine (30 KvA 10 min.)