Bending of sheet metal is an operation that involves the use of force to change the shape of the sheet. Sheet metal is bent to achieve the required form or shape in the manufacturing process. The applied external force only changes the external properties of the sheet. The parameters of one type of sheet metal, such as length and thickness, remain the same. The ductility of sheet metal allows it to undergo a variety of forming processes.

Bending machines for sheet metal help to bend sheet metal with as few errors as possible depending on the processing process.

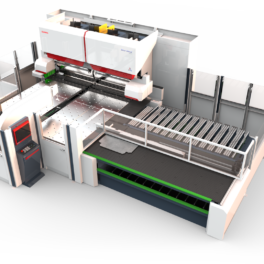

Durma is the world’s leading machine manufacturer and also the world market leader for metalworking machines. The Durma product range covers all the most important areas of metal processing: bending, cutting, stamping and processing of profile materials.

Durma exports its products to 82 countries worldwide. The area of the company’s factory premises covers 150,000 square meters and the company employs more than 1,000 employees. Durma works consistently to achieve the highest standards of metalworking equipment.

Durma is a provider of a very wide spectrum of metalworking equipment. In addition, the company has high-quality service, customer support and training. The company also offers spare parts ready for delivery, which means that repairing a malfunctioning device takes considerably less time.

The SERVO series products are increasingly represented in Durma’s product range. The latest software solutions reduce energy consumption, which means that the devices that came from the factory are ~30% more energy efficient.

Nordcity offers bending machines for sheet metal as well as for pipe and profile processing. Explore our selection and feel free to contact us if you have any questions. We will help you find the best possible bending machine for your company, which would suit the company’s work volumes and other important factors.