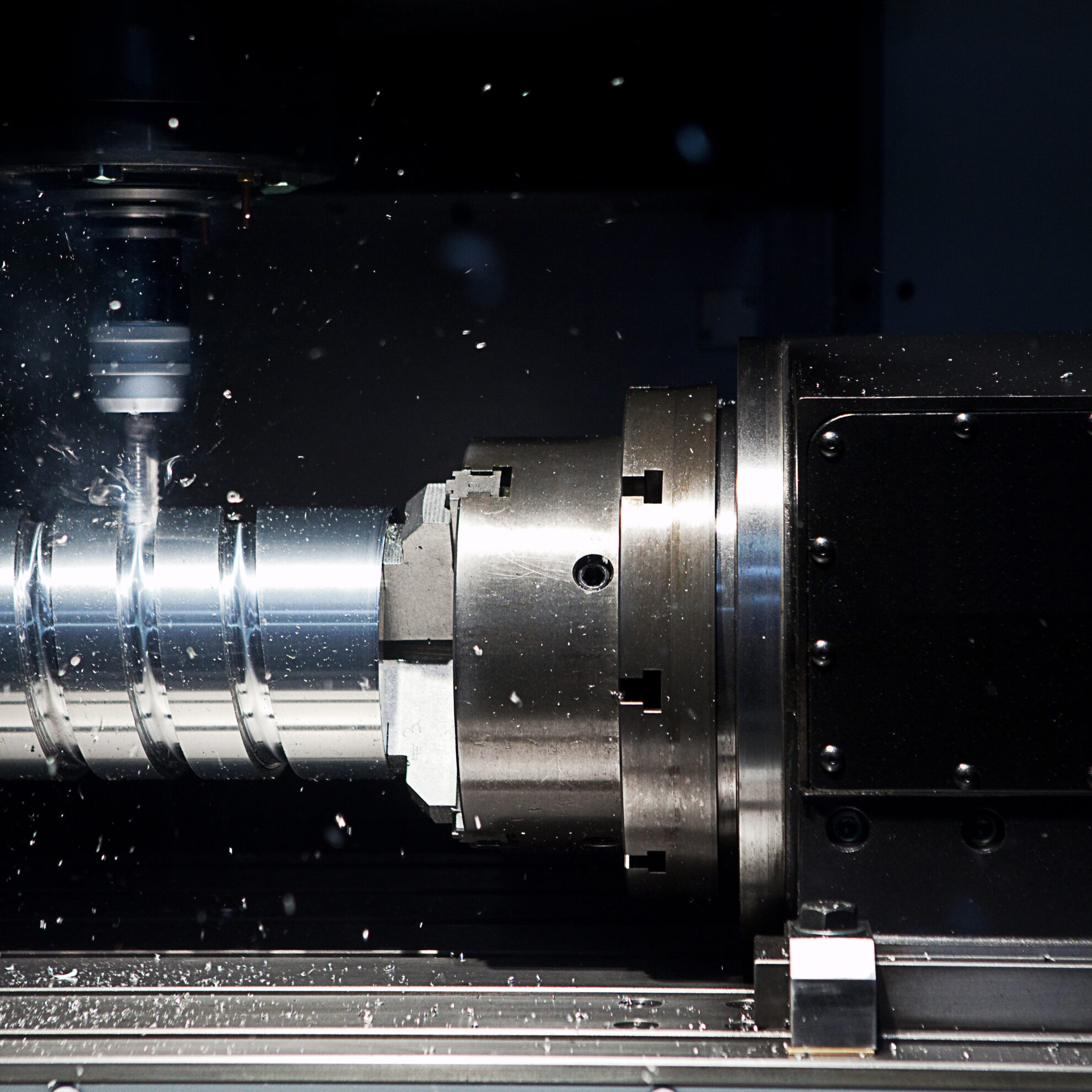

KOVOSVIT SP 280 CNC lathe machine

Max. turning dia: 280 mm

Max. turning length: 550 mm

Max. Workpiece weight: 350 kg

Max.output S1 / S6 – 40%: 22/33 kW

The two machine sizes specified in the name by the maximum machining diameter (180 mm or 280 mm) allow for high productivity including right spindle machining.

Five technological versions for each machine size allow for the perfect choice of your technology from small-scale production to specialized mass production.

The solid base of the machine and the bed ensure high stiffness of the machine.

Deformations of mechanical components of machines are verified using numerical calculation methods – FEM.

Dynamics and stability of the axle movement are checked using modern calculation methods

Spindle units provide high machining efficiency.

The built-in spindle synchronous motors provide high spindle dynamics and efficient rotary C axis.

Line axle support, right headstock or tailstock travels on the track guide, providing high positioning accuracy and interpolated axle movement.

The rigidity of the three-axial version of the upper slide emphasizes the solution with the virtual motion of the Y1 axis, which consists of the interpolation of the real axes X1 and Y ‘including the angle of 30 degrees.

Programmable movement of the tailstock body reduces unnecessary tampering in the machining process

The choice of modern control systems SINUMERIK 840 sl, GE FANUC 0i and GE FANUC 30i guarantee excellent control and programming comfort.

Machines meet your expectations in terms of ease of use, including integrated workshop programming.

Through clamping cylinder (the left headstock)

Solid clamping cylinder (the right headstock)

The left and right spindle locking (motor spindle)

Direct measuring in axis X1

Absolute measuring of linear axes

Tool cooling – 7 bar

Tailstock incl. connection

Machine lighting

Tool kit

Technical documentation

Chucks A5, A6, A8

Special fixtures

Tool holders

High-pressure tool cooling – 17 bar with filtration

The left spindle locking (belt drive)

Fixture blowing – the right headstock

Ejector of parts in the right headstock

Parts catcher

Bar guide

Adaptation for bar feeder

Bar feeder

Manual rinsing

Vapour exhaustion from working space

Automatic tool check

Remote diagnostics

Chip conveyor incl. connection

Chip container with tank

Automatic door opening

Machine state signalling (beacon)

Lifting device

| Technical data | SP 280 | SP 280 MC | SP 280 Y | SP 280 SMC | SP 280 SY | |

| Working space | ||||||

| Swing dia. over bed | 570 | 570 | 570 | 570 | 570 | |

| Max. turning length | mm | 565 | 565 | 565 | 490 | 490 |

| Max. turning dia. | mm | 280 | 280 | 280 | 280 | 280 |

| Max. bar stock capacity – spindle with belt drive | mm | A6: Ø 63 | – | – | – | – |

| Max. bar stock capacity – motor spindle | mm | – | A6: Ø 61 | A6: Ø 61 | A6: Ø 61 | A6: Ø 61 |

| Axis travels | ||||||

| Axes X / Z | mm | 245 / 640 | 245 / 640 | 245 / 640 | 194 / 640 | 194 / 640 |

| Axis Y | mm | – | – | -50 | – | -50 |

| The right headstock Zs | mm | – | – | – | 725 | 725 |

| Rapid traverse | ||||||

| Axes X / Z | min-1 | 30 / 30 | 30 / 30 | 30 / 30 | 30 / 30 | 30 / 30 |

| Main spindle | ||||||

| Belt drive | min-1 | A6: 4700 | – | – | – | – |

| Motor spindle – max. speed | min-1 | – | A6: 4700 | A6: 4700 | A6: 4700 | A6: 4700 |

| Counter spindle A5 | min-1 | – | – | – | A5: 6000 | A5: 6000 |

| Tool head | ||||||

| Number of positions | 12 | 12 | 12 | 12 | 12 | |

| Hole dia. VDI | mm | 40 | 40 | 40 | 40 | 40 |

| Max. speed of tool spindle | min-1 | – | 4000 | 4000 | 4000 | 4000 |

| Tailstock | ||||||

| Sleeve taper – MORSE | Mo 5 | Mo 5 | Mo 5 | – | – | |

| Spindle motor | ||||||

| Output S1 / S6 – 40% | kW | A6: 22 / 33 | – | – | – | – |

| Max. torque S1 / S6 – 40% | Nm | A6: 273 / 410 | – | – | – | – |

| Motor spindle | ||||||

| Output S1 / S6 – 40% | kW | – | 20,9 / 27 | 20,9 / 27 | 20,9 / 27 | 20,9 / 27 |

| Max. torque S1 / S6 – 40% | Nm | – | 200 / 257 | 200 / 257 | 200 / 257 | 200 / 257 |

| Counter spindle | ||||||

| Output S1/ S6 – 40% | kW | – | – | – | 7,5 / 9 | 7,5 / 9 |

| Max. torque S1 / S6 – 40% | Nm | – | – | – | 48 / 57 | 48 / 57 |

| Tool spindle | ||||||

| Output S3 – 40% | kW | – | 8 | 8 | 8 | 8 |

| Max. torque S3 – 40% | Nm | – | 40 | 40 | 40 | 40 |

| Machine dimensions and weight | ||||||

| Length x width x heigth | mm | 3875 x 2122 x 2345 | 3875 x 2122 x 2345 | 3875 x 2122 x 2345 | 3875 x 2122 x 2345 | 3875 x 2122 x 2345 |

| Weight | kg | 7200 | 7500 | 7700 | 7800 | 7900 |