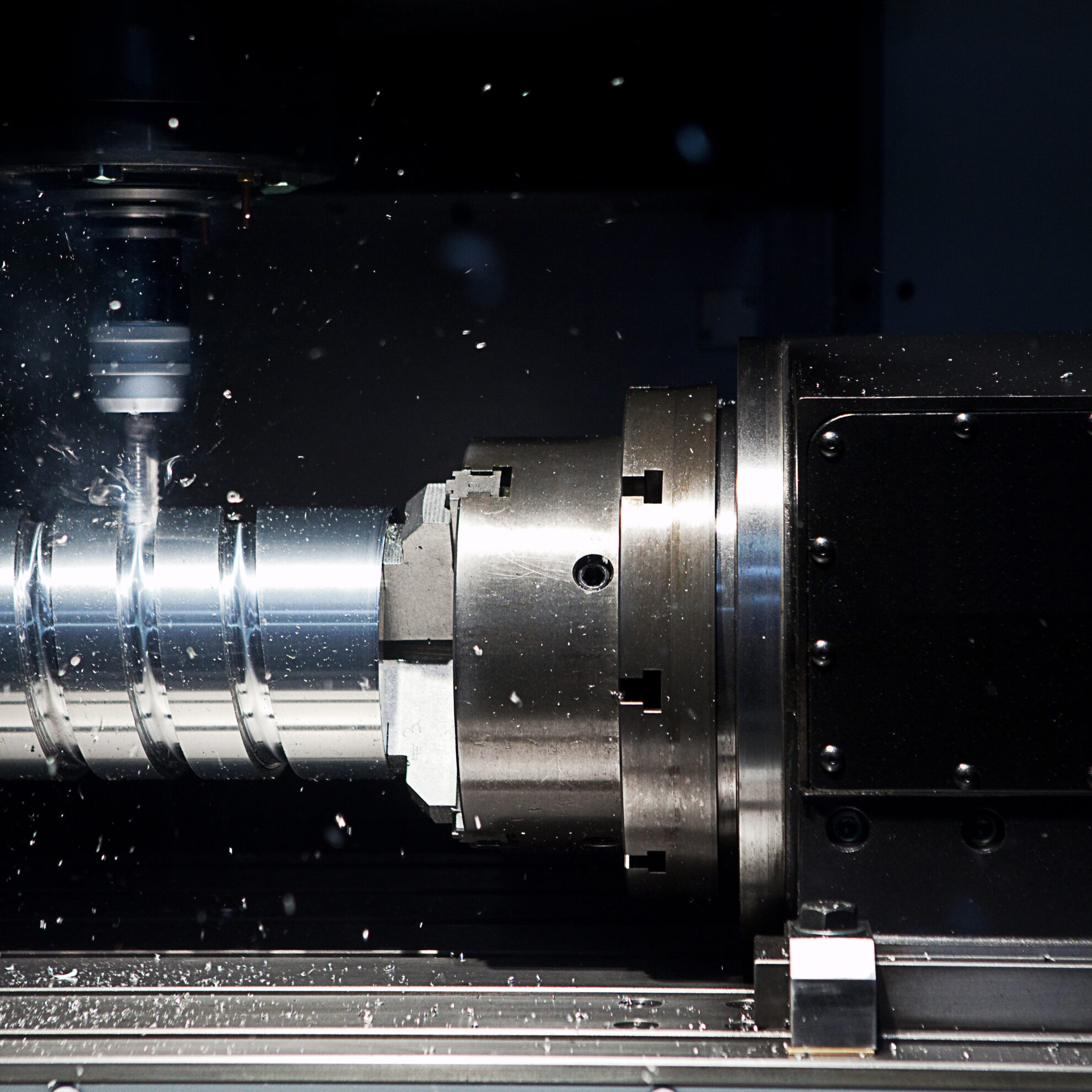

Kovosvit MCV 750 CNC vertical machining center

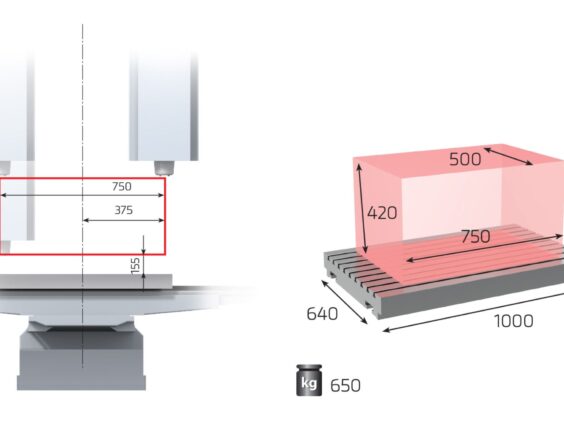

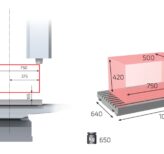

X / Y / Z – 750 / 500 / 500 mm

Table clamping surface: 1 000 x 640 mm

Max. weight on table: 650 Kg

Spindle speed: 12 000 / 18 000 / 24 000 min-1

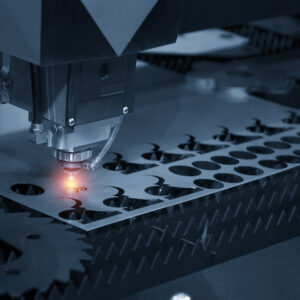

CNC vertical machining center.

Highly efficient machining is guaranteed by the use of highspeed spindles and high rapid traverses.

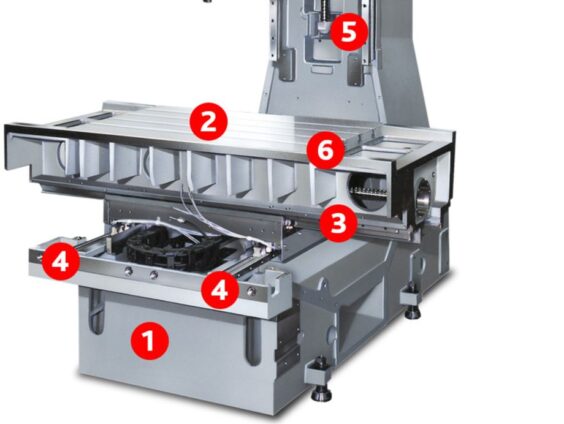

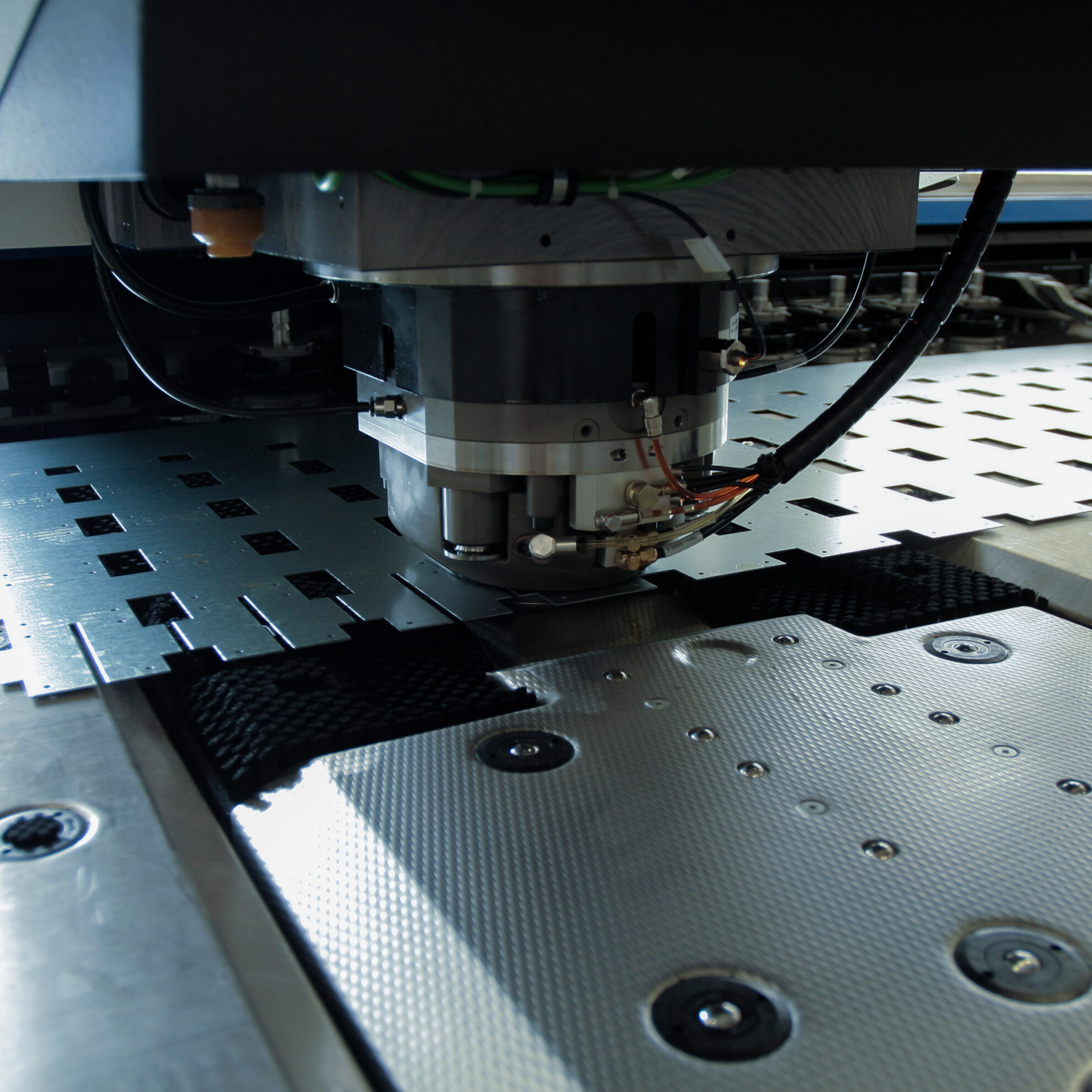

Easy approach to the working space thanks to sliding covers which completely open one corner of the working space.

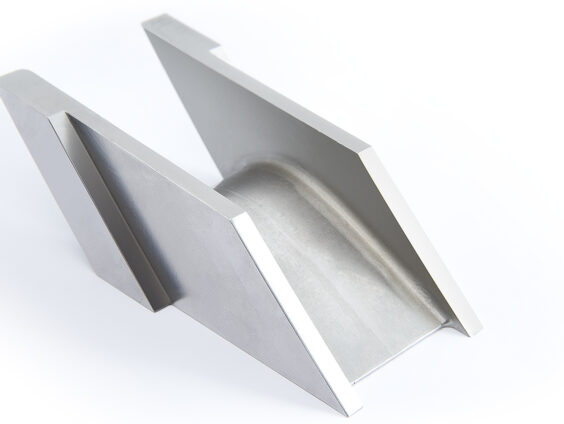

Excellent rigidity of the supporting frame allows both heavy duty machining and very precise machining of complicated workpieces.

High dynamics of linear axes allows high-speed machining of molds. CNC vertical machining center.

The MCV series cnc vertical machining centers are built on a C-shaped supporting frame. Both composition and shapes of the machine supporting frame castings are optimized with regard to the requirements for high rigidity and stability. Use of linear guideways in all linear axes guarantees the required accuracy and dynamics during the machining process.

Electrical equipment 3 × 400V/50Hz

Digital alternating spindle and linear axis control drives HEIDENHAIN / SIEMENS

HEIDENHAIN digital alternating spindle and X, Y, Z, A and C-axis control drives

Direct measuring system

Cooling aggregate for external cooling

Automatic lubrication of moving parts

Central tool clamping

Spindle circulation cooling

Hand wheel

ETHERNET

Operator tool kit

Accompanying documentation

Tool magazine with mechanical arm

Temperature compensation

Control system HEIDENHAIN iTNC530 HSCI / SIEMENS SINUMERIK 840D sl

20 bar internal coolant supply Type AD.

3D infra probes – HEIDENHAIN / RENISHAW / M&H HEXAGON METROLOGY.

Tool probes – HEIDENHAIN / RENISHAW / M&H HEXAGON METROLOGY.

Machine status signalling (beacon).

LOSMA cooling fluid belt filter.

Manual rinsing of workspace.

Rotary and tilting tables (4th and 5th axis) – HOFMANN / KITAGAWA.

External tool air blast.

Oil mist collector Filtermist FX.

Remote diagnostics.

MAS machine monitor.

MAS GSM monitor.

Switchboard air-conditioning.

DXF import (Heidenhain).

AFC adaptive feed control (Heidenhain).

| TECHNICAL DATA | MCV 750 SPEED | MCV 750 SPRINT | MCV 750 RAPID | |

| Table | ||||

| Table clamping surface | 1000 x 640 | 1000 x 640 | 1000 x 640 | |

| T-slots (number×width×spacing) | mm | 4 x 18 x 125 | 4 x 18 x 125 | 4 x 18 x 125 |

| Max. weight on table | kg | 650 | 650 | 650 |

| Working range | ||||

| X-axis | mm | 750 | 750 | 750 |

| Y-axis | mm | 500 | 500 | 500 |

| Z-axis | mm | 500 | 500 | 500 |

| Distance from spindle nose to table clamping surface | mm | 145 – 645 | 155 – 665 | 155 – 665 |

| Spindle | ||||

| Spindle taper | ISO 40 / HSK A63 | HSK A63 | HSK A63 | |

| Max. speed | min-1 | 12 000 | 18 000 | 24 000 |

| Speed change | infinitely variable | infinitely variable | infinitely variable | |

| Feed rate | ||||

| Working feed rate X, Y, Z | mm.min-1 | 1 – 40 000 | 1 – 40 000 | 1 – 40 000 |

| Rapid traverse X, Y, Z | m.min-1 | 40 | 40 | 40 |

| Tool magazine | ||||

| Magazine capacity | 24 | 24 | 24 | |

| Max. tool length | mm | 350 | 350 | 350 |

| Max. tool dia. | mm | 77 | 77 | 77 |

| Max. tool dia. – adjacent stations empty | mm | 150 | 150 | 150 |

| Change time of adjacent tool | s | 4 | 4 | 4 |

| Max. tool weight | kg | 6,5 | 6,5 | 6,5 |

| Motor | ||||

| Spindle motor output – SIEMENS (S1/S6 – 40%) | kW | 32 / 48 | 25 / 35 | 19 / 26,7 |

| Nominal torque SIEMENS (S1/S6 – 40%) | Nm | 130 / 200 | 86 / 120 | 60 / 86 |

| Max. total machine input | kVa | 32 | 30 | 35 |

| Accuracy ČSN ISO 230 – 2 | ||||

| Measuring system X, Y, Z | direct | direct | direct | |

| Positioning accuracy of coordinates | mm | 0,01 | 0,01 | 0,01 |

| Accuracy of repeatability | mm | 0,004 | 0,004 | 0,004 |

| Air operating pressure | MPa | 0,55 – 0,6 | 0,55 – 0,6 | 0,55 – 0,6 |

| Machine dimensions (l x w x h) | mm | 3700 x 2220 x 2735 | 3700 x 2220 x 2735 | 3700 x 2220 x 2735 |

| Machine weight | kg | 5250 | 5100 | 5100 |